thannara123

Advanced Member level 5

- Joined

- Jan 7, 2010

- Messages

- 1,602

- Helped

- 122

- Reputation

- 244

- Reaction score

- 116

- Trophy points

- 1,353

- Activity points

- 10,635

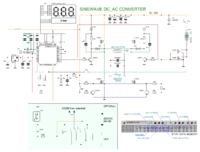

You mean circuit from message #326? or something else?

i Meant the latest version of this thread