pal114525

Member level 5

Hi,

Would you be kind to explain me the following point:

If my design works on DC voltage, how it will pick the mains hum ( at 50 Hz)?

Thanks & Regards.

- - - Updated - - -

Hi,

Would you be kind to explain me the following point:

If my design works on DC voltage, how it will pick the mains hum ( at 50 Hz)?

Thanks & Regards.

- - - Updated - - -

Hi,

Would you be kind to tell me the following point:

1. What should be the no. of turns of the transmit coil and the receiver coil for a walk-through metal detector?

2. What should be its shape, Elliptical or Rectangular for a walk-through metal detector?

Thanks.

- - - Updated - - -

Hi,

Would you be kind to tell me the following point:

1. What should be the no. of turns of the transmit coil and the receiver coil for a walk-through metal detector?

2. What should be its shape, Elliptical or Rectangular for a walk-through metal detector?

Thanks.

- - - Updated - - -

Hi,

Thanks for your valuable feedback.

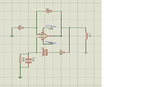

I have attached the schematic of the Transmitter circuit for a walk-through metal detector. I am using Wien Bridge oscillator for generating 18 KHz frequency and transmitting it through a transmitter coil into the air.

Would you be kind to tell me the following point:

1. What would be the optimum no. of turns of the transmitter coil for a walk-through metal detector for 18 KHz signal?

2 Should it be an elliptical or rectangular in shape?

Thanks.

Would you be kind to explain me the following point:

If my design works on DC voltage, how it will pick the mains hum ( at 50 Hz)?

Thanks & Regards.

- - - Updated - - -

Hi,

Would you be kind to explain me the following point:

If my design works on DC voltage, how it will pick the mains hum ( at 50 Hz)?

Thanks & Regards.

- - - Updated - - -

Hi,

Would you be kind to tell me the following point:

1. What should be the no. of turns of the transmit coil and the receiver coil for a walk-through metal detector?

2. What should be its shape, Elliptical or Rectangular for a walk-through metal detector?

Thanks.

- - - Updated - - -

Hi,

Would you be kind to tell me the following point:

1. What should be the no. of turns of the transmit coil and the receiver coil for a walk-through metal detector?

2. What should be its shape, Elliptical or Rectangular for a walk-through metal detector?

Thanks.

- - - Updated - - -

Hi,

Thanks for your valuable feedback.

I have attached the schematic of the Transmitter circuit for a walk-through metal detector. I am using Wien Bridge oscillator for generating 18 KHz frequency and transmitting it through a transmitter coil into the air.

Would you be kind to tell me the following point:

1. What would be the optimum no. of turns of the transmitter coil for a walk-through metal detector for 18 KHz signal?

2 Should it be an elliptical or rectangular in shape?

Thanks.