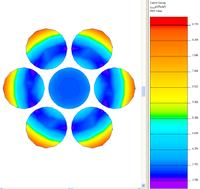

The initial issue arose to ask if the wire size of that design is appropriate or not, and the discussion came to the losses generated by the AC component subjected to the skin effect. However, the losses generated by DC component also should be considered to resize the wire, once there will have some increase on wire temperature due to this component.