V

volker_muehlhaus

Guest

I found that I needed an unusual high number of filaments

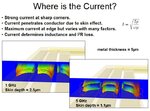

That was the effect that I see in Sonnet, too. Compared to the mesh that I use for RFIC inductors, this one needs more cells across the line width. When I think about this, the reason might be the ratio of skin depth (9µm @ 50MHz) and line width (6mm!). That ratio is less extreme in typical RFIC cases, which I usually analyze.

Anyway, I promised a new data point and here it is: with much finer meshing across the line, my Sonnet thick metal result seems to converge to Q ~380.

Best regards

Volker