yefj

Advanced Member level 5

- Joined

- Sep 12, 2019

- Messages

- 1,557

- Helped

- 1

- Reputation

- 2

- Reaction score

- 5

- Trophy points

- 38

- Activity points

- 9,377

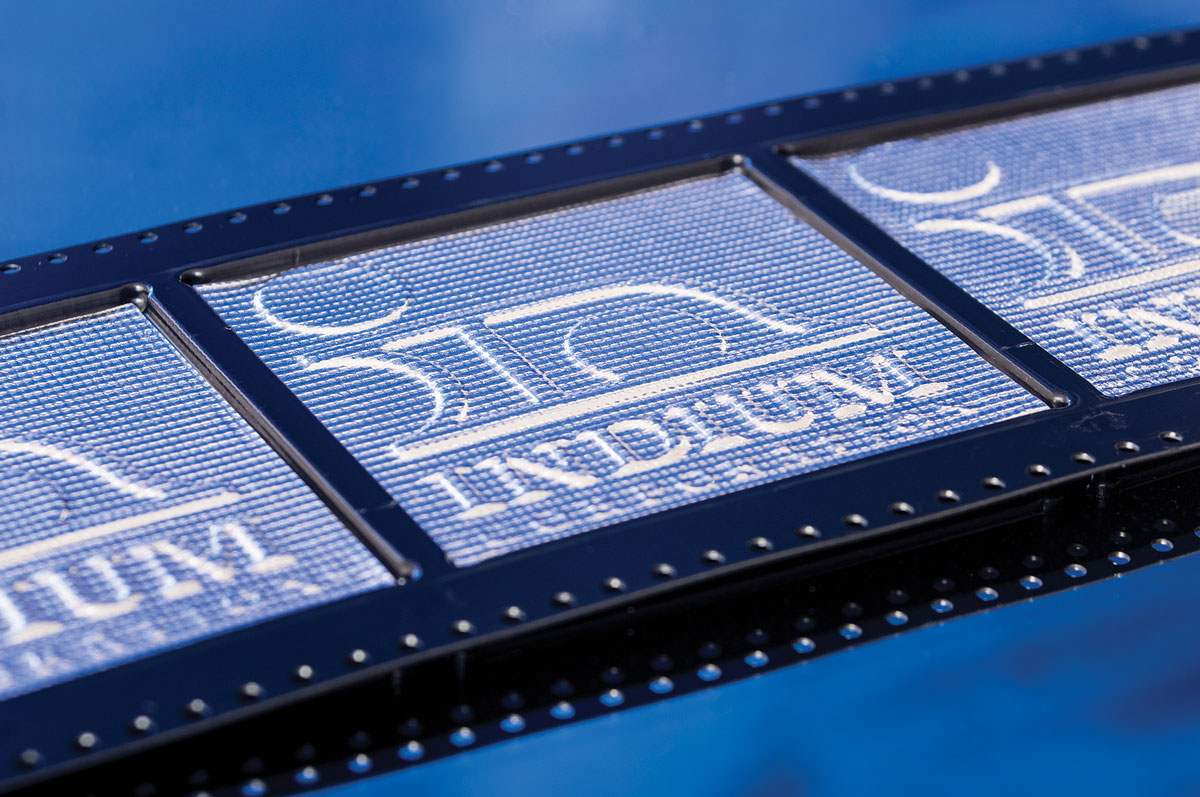

Hello,I Have the following PCB shown in the photo below ,which is glued on a heatsink.Is there a good glue you reccomend

which both conduct electricity and heat as best as possible?

Thanks.

which both conduct electricity and heat as best as possible?

Thanks.