pic.programmer

Advanced Member level 3

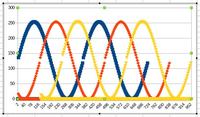

That is how I did and it shifts sine wave 2 and 3 but the angle starts from 120 and 270 degrees for sine 1 and sine 2 and it keeps on shifting and cycling.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

APFCON=0X00

Then pins functions became as follows:

CCP1►RC2

CCP2►RC1

CCP3►RC6

#include "C:\\projects\\3Phase_PWM\\3phase_PWM_Auto.h"

unsigned char P1_index, P2_index, P3_index; // pointers to sine table

unsigned char TableSize; // number of entries in the sine table

int FrequencyValue = 0;

const unsigned char Sine_Table[90] = {127,136,145,153,162,170,179,187,194,202,209,215,

221,227,232,237,241,245,248,250,252,253,254,254,253,252,250,248,245,241,237,

232,227,221,215,209,202,194,187,179,170,162,153,145,136,127,118,109,101,92,

84,75,67,60,52,45,39,33,27,22,17,13,9,6,4,2,1,0,0,1,2,4,6,9,13,17,22,27,33,

39,45,52,60,67,75,84,92,101,109,118};

//*******************************************************************************

//

void UserInterrupt()

{

#asmline SETPCLATH UserIntReturn,-1 ; SETPCLATH for interrupt routine

#asmline goto UserIntReturn ; Assembler - go back to interrupt routine

}

//*******************************************************************************

//

void UserInitialise()

{

TableSize = sizeof(Sine_Table);

P1_index = 0; // reference phase angle = 0 degrees

P2_index = TableSize / 3; // phase angle = 120 degrees

P3_index = P2_index * 2; // phase angle = 240 degrees

ADCON0 |= (1 << ADGO); // start a new conversion

}

//*******************************************************************************

//

void UserLoop()

{

}

//*******************************************************************************

// called when ADC conversion is complete

void ADC_Finished()

{

FrequencyValue = ((int)ADRESH << 8) + (int)ADRESL; // full ADC result

FrequencyValue >>= 4; // scale to 8-bits

ADCON0 |= (1 << ADGO); // start a new conversion

}

//*******************************************************************************

// called when timer 0 overflows

void T0_Overflow()

{

if(++P1_index == TableSize) P1_index = 0; // point to next sine value

if(++P2_index == TableSize) P2_index = 0;

if(++P3_index == TableSize) P3_index = 0;

SetPWM1Volts(Sine_Table[P1_index]);

SetPWM2Volts(Sine_Table[P2_index]);

SetPWM3Volts(Sine_Table[P3_index]);

TMR0 = FrequencyValue; // reload with sine stepping rate

}

Assuming you actually need to maintain constant torque, there are two methods:

1. adjust the low and high PWM values according to the speed so the resulting voltage changes,

2. keep the PWM the same and adjust the DC supply to the PWM drivers.

For method 1, you have to decide the voltages needed at lowest speed and scale the PWM figures accordingly. Then multiply the table values by a figure derived from the speed before sending them to the PWM generators. Make sure the multiplied number does not exceed the maximum to PWM can accept or you will get a 'wrap around' effect in the voltage and severe waveform distortion.

For method 2. you need a method to control the DC source to the motor drivers, this could be another PWM signal or a signal generated by any other analog means. As the frequency increases, the DC supply should be increased in proportion.

There is a good reference at **broken link removed** but the code examples are for TI DSP products. The flow charts and text will explain the principles quite well.

You also need to decide whether you are simply producing a constant V/F and hoping the motor responds or if you are going to employ a feedback mechanism to combat load variations.

Brian.