theboom

Member level 2

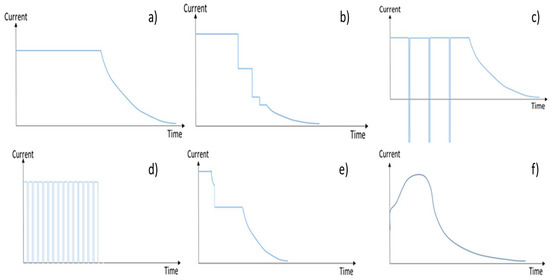

My application is a single-cell lithium battery charger. I assume constant-voltage with current-limiting would work (but i may be mistaken).

There will be a group of disconnected cells (not a battery pack). All the cells in the group will be the same chemistry as each other. Need to support both Li-ion and LiFePO.

A single SMPS will supply regulated constant voltage for all the cells. So i think all that's needed is a current limiter on each cell.

The LM338 seems to have low-parts limiter, but apparently not available in SMD package, and (i'm told) not low-heat.

I found this current limiter for the TL431, but i'm told it will disconnect when limit is reached, rather than simply limit current to desired level.

If possible, I like the idea of shunting the excess current to other cells in the group, rather than wasting it as heat.

I'd be fine with a low-parts single-cell charger IC. Analog offers several, such as the LTM8026, but much too expensive for my application.

There will be a group of disconnected cells (not a battery pack). All the cells in the group will be the same chemistry as each other. Need to support both Li-ion and LiFePO.

A single SMPS will supply regulated constant voltage for all the cells. So i think all that's needed is a current limiter on each cell.

The LM338 seems to have low-parts limiter, but apparently not available in SMD package, and (i'm told) not low-heat.

I found this current limiter for the TL431, but i'm told it will disconnect when limit is reached, rather than simply limit current to desired level.

If possible, I like the idea of shunting the excess current to other cells in the group, rather than wasting it as heat.

I'd be fine with a low-parts single-cell charger IC. Analog offers several, such as the LTM8026, but much too expensive for my application.

Last edited: