3v0

Junior Member level 3

modifying inkjet printer pcb

Pulsar https://www.pulsarprofx.com/ makes a transfer paper and foil system that works very well. I have made about a half dozen boards with their system and had good results.

The system uses a foil to cover the toner. This helps prevent pin holes and in general makes the artwork hold up better during etching. They have several interesting tips on there site including how to set the iron temperature, how to simulate a laminator using a wood dowel, and how to etch 1/2 copper boards in about 2 minutes.

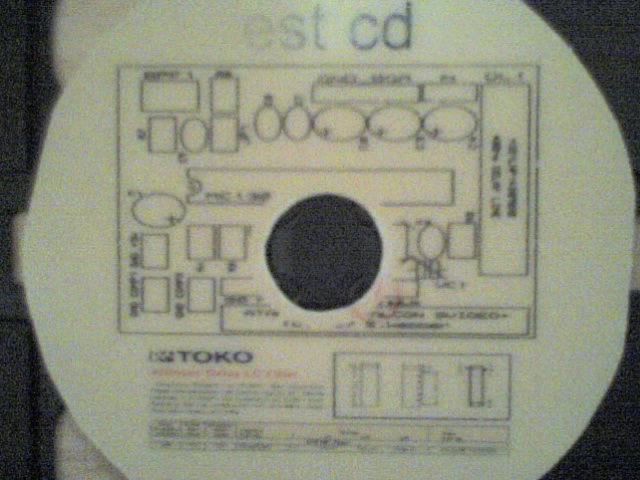

This is the first board I did with the system. Since then I have made denser and DS boards. The cost is less then $0.25 per square inch.

Most of the traces are .024 inches. you can see a bit of .016 in at least one spot. IIRC the smallest line on the lower left is .01 inches.

**broken link removed**

Pulsar https://www.pulsarprofx.com/ makes a transfer paper and foil system that works very well. I have made about a half dozen boards with their system and had good results.

The system uses a foil to cover the toner. This helps prevent pin holes and in general makes the artwork hold up better during etching. They have several interesting tips on there site including how to set the iron temperature, how to simulate a laminator using a wood dowel, and how to etch 1/2 copper boards in about 2 minutes.

This is the first board I did with the system. Since then I have made denser and DS boards. The cost is less then $0.25 per square inch.

Most of the traces are .024 inches. you can see a bit of .016 in at least one spot. IIRC the smallest line on the lower left is .01 inches.

**broken link removed**

Last edited by a moderator: