Kamran786

Newbie level 6

Dear Members,

I hope you are all doing well.

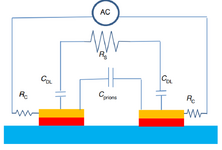

I am a PhD student and completely new to circuit design. I need a compact-sized circuit and prefer not to use an impedance analyzer due to its bulkiness. I am looking to build a circuit capable of automatically measuring the impedance of a sensor in the range of 1MΩ to 30MΩ. However, I am unsure how to approach this task, especially with the various methods available for impedance measurement. I’m not certain which method would be most suitable for automatic measurement in my case. There are different impedance measurement modules, but none seem to have the capability to measure impedance automatically within this range. My sensor’s equivalent circuit is a resistor in parallel with a capacitor.

Could someone guide me through the procedure to build the circuit design? Specifically, I would like to know which components I should purchase to begin building the circuit. If there are any tutorials or resources that you could recommend, that would be very helpful as well.

So far, I have only completed the integration of a DDS (Direct Digital Synthesis) with an Arduino to generate a signal with a frequency of 1 kHz and an amplitude of 500mV, which meets my signal requirements. However, I am uncertain about how to proceed with the remaining circuit design.

Your help in this matter would be greatly appreciated.

I hope you are all doing well.

I am a PhD student and completely new to circuit design. I need a compact-sized circuit and prefer not to use an impedance analyzer due to its bulkiness. I am looking to build a circuit capable of automatically measuring the impedance of a sensor in the range of 1MΩ to 30MΩ. However, I am unsure how to approach this task, especially with the various methods available for impedance measurement. I’m not certain which method would be most suitable for automatic measurement in my case. There are different impedance measurement modules, but none seem to have the capability to measure impedance automatically within this range. My sensor’s equivalent circuit is a resistor in parallel with a capacitor.

Could someone guide me through the procedure to build the circuit design? Specifically, I would like to know which components I should purchase to begin building the circuit. If there are any tutorials or resources that you could recommend, that would be very helpful as well.

So far, I have only completed the integration of a DDS (Direct Digital Synthesis) with an Arduino to generate a signal with a frequency of 1 kHz and an amplitude of 500mV, which meets my signal requirements. However, I am uncertain about how to proceed with the remaining circuit design.

Your help in this matter would be greatly appreciated.