So I make my question simple. How we calculate standard charging voltage, current and time of a battery?

This is long story, I think on EDABoard you can find tons of material about that.

Simple answer is use battery manufacturer instructions and guidance. Download battery datasheet and see all spec.

Usually is C/10 or C/20 for charging / discharging for guranteed life.

This means charging process in 10h or 20h.

Example for 55Ah C/10 : 55Ah / 10 = 5,5A is recommended current of charging, and its need 10h to recharge complete empty battery.

For discharge formula is the same C/10, no faster discharge then C/10 55Ah/10=5,5A. that means battery of 55Ah can give 5,5A during 10h of discharging. If you increase current you cant expect power production of full capacity.

Lead acid generaly have two types starter and deep cycle. Charging/discharging methods and process are not the same for both. Also there is many different battery chemical tech.

Charging voltage depends from temperature.

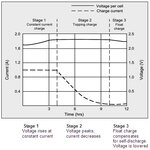

Float charging 13,5V-13,8V (depends from temperature).

Cycling voltage is in range 14,2V but in starting stages of charging.

You can make battery charger with float charge voltage 13,8V (for up to 30C) and limit current to 5A, for car batteries 55A, its 55Ah/5A=11h of recharging when battery is complete empty.

Example: Use LM338K (TO3), transformer 18V, and rest parts. Set float voltage to 13,8V and LM338K have internal thermal and overcurrent protection, and current when battery is empty will be limited to 5A. For smaller 12V 7,2Ah batteries use LM317, and respect manufacturer datasheet data.

Lead acid should have voltage and current control of charging.

Lead acid should charge with appropriate current according to size of battery, that will satify recharging time period to be in normal range (10h). This also prevent sulfatisation process to appear on lead plates. Take in mind that also overcharging can cause lead plates sulfatisation.

One of good tests for lead acid batteries, I say one of tests, is monitoring internal resistance of battery, monitoring from period when it was new, and through aging and battery life. If internal resistance is over 30mΩ thats bad for car battery 45-55Ah-72Ah, bigger 120Ah-200Ah should have 10mΩ as normal.

You can view one interesting project called "Deep-Cycle Charger for 12V batteries" by John Clarke, EPE Mag Jan/Feb 2007. Its not just for deep cycle type, its also for starter type.