omid_juve

Full Member level 1

74hc595 problems

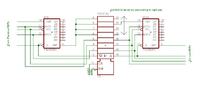

we have these results

when we use .1uf cap on every 74hc595 power rail the problem is got worst

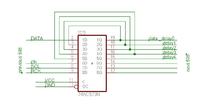

and so we take them and put 74hc245 on the way of DS, SCK,LCK of the twentieth

74hc595 to the end of the display(twenty fifth 74hc245) the problem is got better

and with this configuration plus a 27pf cap on the last 74hc595 LCK pin the problem is

solved!!! if anybody know why the problem is becoming worst when we use .1uf cap on every 74hc595's power rail plz describe it for me .

thanks for every one's help

we have these results

when we use .1uf cap on every 74hc595 power rail the problem is got worst

and so we take them and put 74hc245 on the way of DS, SCK,LCK of the twentieth

74hc595 to the end of the display(twenty fifth 74hc245) the problem is got better

and with this configuration plus a 27pf cap on the last 74hc595 LCK pin the problem is

solved!!! if anybody know why the problem is becoming worst when we use .1uf cap on every 74hc595's power rail plz describe it for me .

thanks for every one's help