cntntn

Junior Member level 1

Hi,

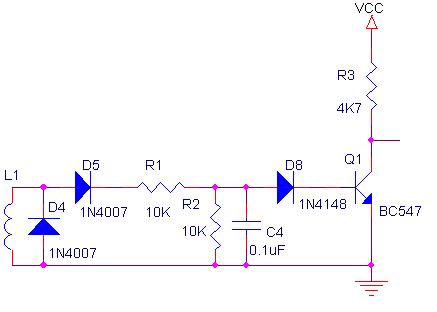

With my Arduino UNO board I need to detect how many pulse of electric current come to a spark plug cap, when the engine works.

There are any sensor can do that ?

The bigger problem (I think) is the voltage of current (can be higher then that of 20000v), but most of the RPM counter on bike works in this way, so there must be a way...

Thanks to all who help me :smile:

With my Arduino UNO board I need to detect how many pulse of electric current come to a spark plug cap, when the engine works.

There are any sensor can do that ?

The bigger problem (I think) is the voltage of current (can be higher then that of 20000v), but most of the RPM counter on bike works in this way, so there must be a way...

Thanks to all who help me :smile: