salah_edu

Junior Member level 1

- Joined

- Mar 28, 2008

- Messages

- 17

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,281

- Activity points

- 1,399

Hello,

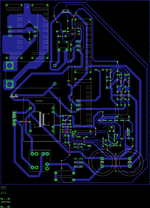

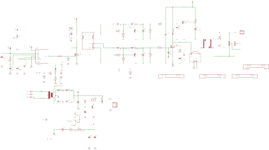

I am trying to design a 100A smps for welding , the design is two switch ( IGBT) forward converter using current transformer for feedback in primary current, the switching tranformer

is a commercialy available toroid transfomer recovred from already working welder , the issue is when i connect the board to ac mains and after a few seconds the ibgts fail without getting hot and they are shorted between ( Gate Emitter and collerctor) i tried to add a capcitor for 22nf beween Gate and emiiter to remove miller effect but i still have the same issue.

you find attached the schematic and the pcb layout.

Regards.

I am trying to design a 100A smps for welding , the design is two switch ( IGBT) forward converter using current transformer for feedback in primary current, the switching tranformer

is a commercialy available toroid transfomer recovred from already working welder , the issue is when i connect the board to ac mains and after a few seconds the ibgts fail without getting hot and they are shorted between ( Gate Emitter and collerctor) i tried to add a capcitor for 22nf beween Gate and emiiter to remove miller effect but i still have the same issue.

you find attached the schematic and the pcb layout.

Regards.