zeb59

Junior Member level 3

Hi,

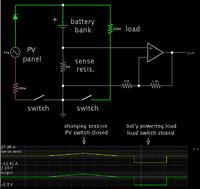

I am trying to design a 50 Amps capable battery charger for charging a 2000 AH lead acid battery bank.

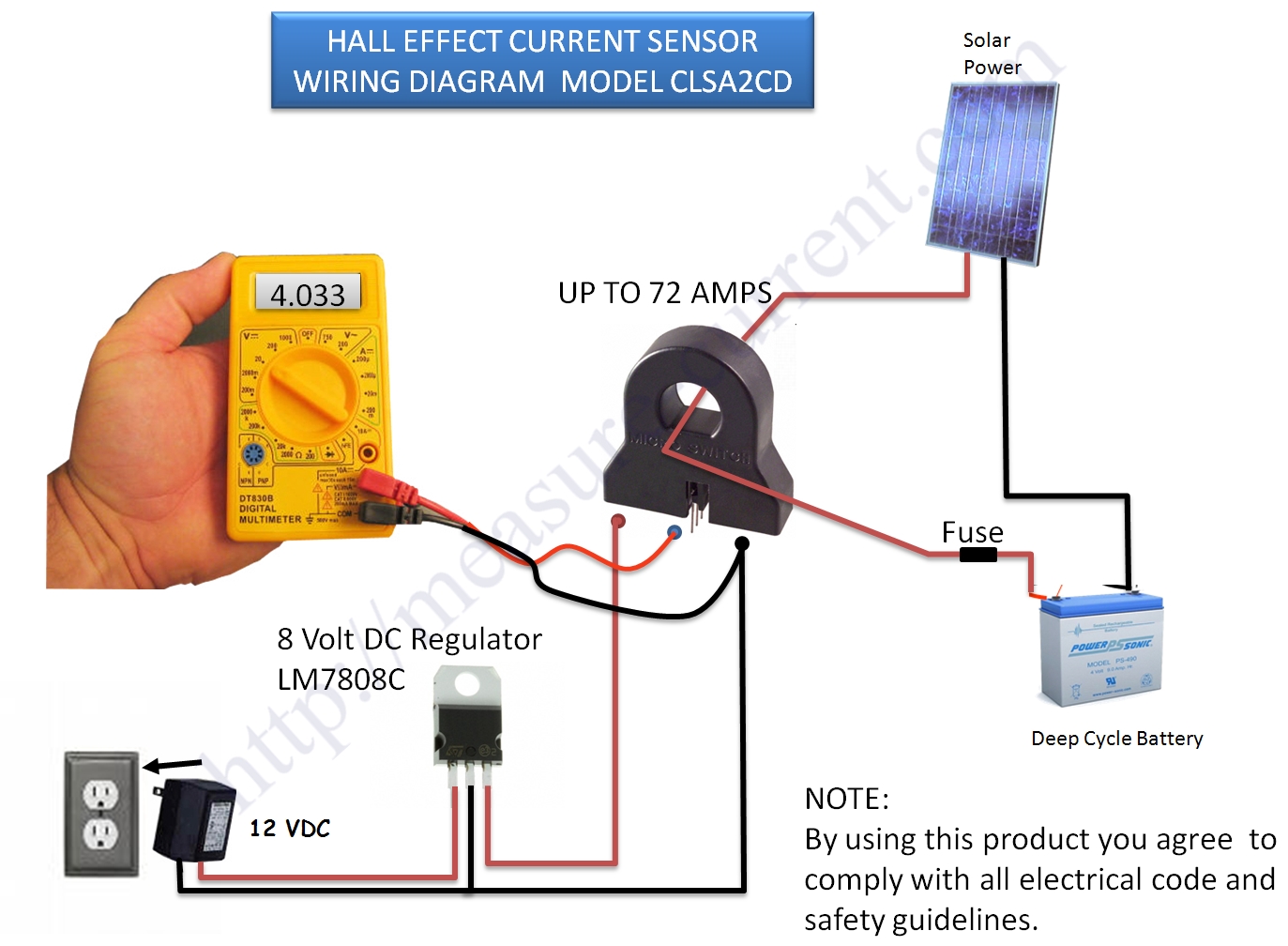

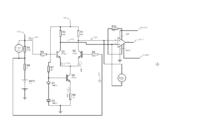

For the above purpose I would like to measure the battery charge/discharge current. I initially tried ACS712 because it offers the possibility of galvanic isolation. However that route had to be abandoned because voltage has to be measured which means galvanic isolation is not possible. Now I am toying with high-side measurement of current. The problem here in Pakistan is the non or difficult availability of high side measurement ICs. So I am trying to do some ab-initio design of the input stage using discrete components (or CA3086 type) matched transistor array. The array would be followed by an IN-AMP (I am using the easily available AD620). The current measurement is by a shunt resistor (0.0004 ohms). My initial circuit using BC547 BJTs is shown below:

I would like the forums valuable views on the design and any corrections that I should incorporate.

TIA

Zeb

I am trying to design a 50 Amps capable battery charger for charging a 2000 AH lead acid battery bank.

For the above purpose I would like to measure the battery charge/discharge current. I initially tried ACS712 because it offers the possibility of galvanic isolation. However that route had to be abandoned because voltage has to be measured which means galvanic isolation is not possible. Now I am toying with high-side measurement of current. The problem here in Pakistan is the non or difficult availability of high side measurement ICs. So I am trying to do some ab-initio design of the input stage using discrete components (or CA3086 type) matched transistor array. The array would be followed by an IN-AMP (I am using the easily available AD620). The current measurement is by a shunt resistor (0.0004 ohms). My initial circuit using BC547 BJTs is shown below:

I would like the forums valuable views on the design and any corrections that I should incorporate.

TIA

Zeb