boylesg

Advanced Member level 4

- Joined

- Jul 15, 2012

- Messages

- 1,023

- Helped

- 5

- Reputation

- 10

- Reaction score

- 6

- Trophy points

- 1,318

- Location

- Epping, Victoria, Australia

- Activity points

- 11,697

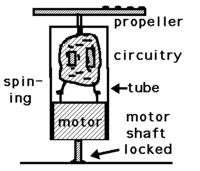

How would you go about transmitting power wireless from the stationary part of a POV clock to the spinning part?

Would you use an an SMPS arrangement and would these work without a core, i.e. just two loops of wire in close proximity?

If so does anyone no a good URL that explains the very basics of designing a SMPS.

Would you use an an SMPS arrangement and would these work without a core, i.e. just two loops of wire in close proximity?

If so does anyone no a good URL that explains the very basics of designing a SMPS.