RachelAnne289

Newbie level 5

I think refrigerator compressor motors are single-phase motors. It’s cheap, and it can run right off the mains single-phase supply.

But single-phase motors don’t start very well - depending on what the position the motor is in, it might start rotating in the wrong direction for the pump to work; or it might just sit there, oscillating, not generating enough torque to even make the first rotation.

So most single-phase motors actually start with two-phases, the second phase helping give the rotor the torque vector it needs to start spinning in the right direction.

Once the motor is spinning, the second phase is no longer needed.

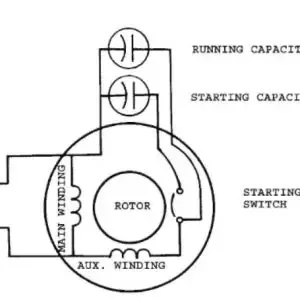

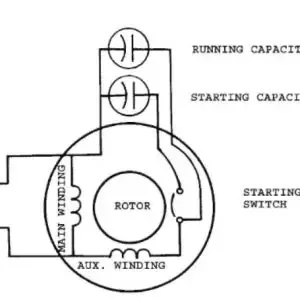

The second phase has to be phase-shifted relative to the main phase to produce the torque vector, so a large capacitor (the starting capacitor) is added to provide the phase shift. Then, since the phase is no longer needed during normal running, a switch disconnects the starting capacitor and second phase. This switch can either be electrically controlled, or a centrifugal switch.

Disconnecting the starting capacitor when it’s not needed improves the lifetime of the capacitor, and depending on motor design, can also improve the running efficiency and power factor, so it’s desirable to be able to disconnect the capacitor and second phase when not needed.

However, there are single-phase motor designs, called start-run motors that have both a large starting capacitor(maybe solid state capaciator?) that provides a big phase shift for starting; and a permanently-connected run capacitor that provides a smaller phase shift for a second phase in continuous operation.

Starting capacitors are not the only method of ensuring a single-phase motor can start, there are various other techniques including shaded poles, asymmetric poles, embedded magnets, etc. Starting single-phase motors is a whole discipline unto itself.

But single-phase motors don’t start very well - depending on what the position the motor is in, it might start rotating in the wrong direction for the pump to work; or it might just sit there, oscillating, not generating enough torque to even make the first rotation.

So most single-phase motors actually start with two-phases, the second phase helping give the rotor the torque vector it needs to start spinning in the right direction.

Once the motor is spinning, the second phase is no longer needed.

The second phase has to be phase-shifted relative to the main phase to produce the torque vector, so a large capacitor (the starting capacitor) is added to provide the phase shift. Then, since the phase is no longer needed during normal running, a switch disconnects the starting capacitor and second phase. This switch can either be electrically controlled, or a centrifugal switch.

Disconnecting the starting capacitor when it’s not needed improves the lifetime of the capacitor, and depending on motor design, can also improve the running efficiency and power factor, so it’s desirable to be able to disconnect the capacitor and second phase when not needed.

However, there are single-phase motor designs, called start-run motors that have both a large starting capacitor(maybe solid state capaciator?) that provides a big phase shift for starting; and a permanently-connected run capacitor that provides a smaller phase shift for a second phase in continuous operation.

Starting capacitors are not the only method of ensuring a single-phase motor can start, there are various other techniques including shaded poles, asymmetric poles, embedded magnets, etc. Starting single-phase motors is a whole discipline unto itself.