Spork

Member level 3

Hello,

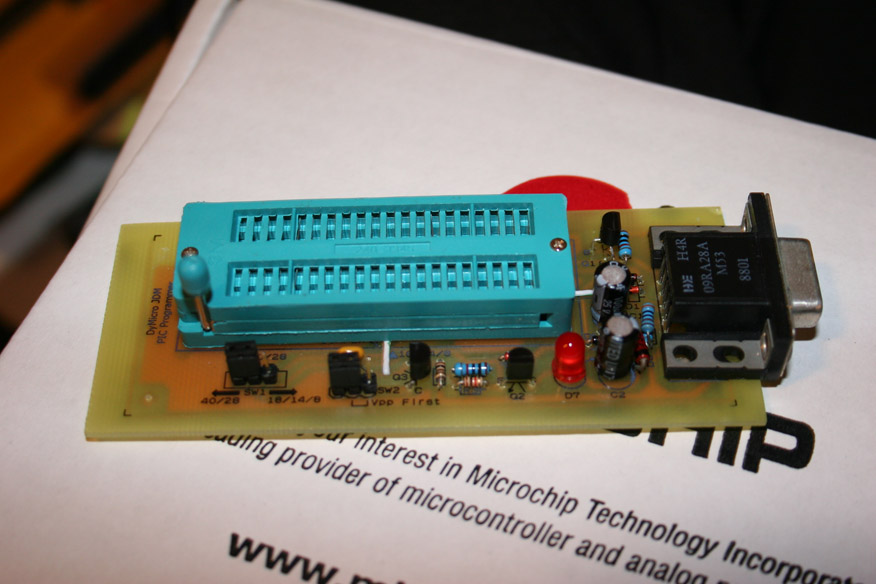

I have made many PCB's at home, but they all have a strange green see-through color.

On computers and other devices I have seen a much nicer green, and I'm not sure what it is.

I have thought it may be soldermask, but I looked around and that did not seem promising.

I also found sealant (like epoxy) that has color, but on the PCB's, the "color" doesn't touch the solder points.

Finally, I have also seen red, blue, yellow, and purple PCBs, which makes me wonder what was used.

Does anyone know what I could use to make colored PCB that is not as see-through as my current ones?

I think blue/yellow would look much better because my silk-screen layer is always black.

Thanks,

Spork

I have made many PCB's at home, but they all have a strange green see-through color.

On computers and other devices I have seen a much nicer green, and I'm not sure what it is.

I have thought it may be soldermask, but I looked around and that did not seem promising.

I also found sealant (like epoxy) that has color, but on the PCB's, the "color" doesn't touch the solder points.

Finally, I have also seen red, blue, yellow, and purple PCBs, which makes me wonder what was used.

Does anyone know what I could use to make colored PCB that is not as see-through as my current ones?

I think blue/yellow would look much better because my silk-screen layer is always black.

Thanks,

Spork