d123

Advanced Member level 5

Hi!

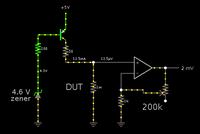

The circuit below is not functioning as I'd hoped/expected. This is an experiment making a milli ohmeter, that is the purpose of this circuit; I was unable to breadboard it, or simulate a couple of the ICs, so I just made a prototype to see what would happen, therefore it's very rough and ready.

Are there any obvious mistakes in the design that would cause a predicted 100mA constant current appear to be in fact 2A?

The voltage regulators are supposed to be putting out 5V and 100mA...

- The 73801 which supplies the ICs does output 5.02V, not sure of its current output (yet) as that is not an issue.

- The 73801 which feeds the DUT resistor part of the circuit supplies a poor 1V, and according to the multimeter is blasting out 2.1A down to 1.6A by the time the 555 "Start" pulse ends. Bad for the battery too. I understand this high current is why the output voltage is only 1V, and not 5.02V.

(The 555 "Start button" sends a signal to the 73801 "enable" pin, otherwise the 73801 for the DUT resistor has 0V output).

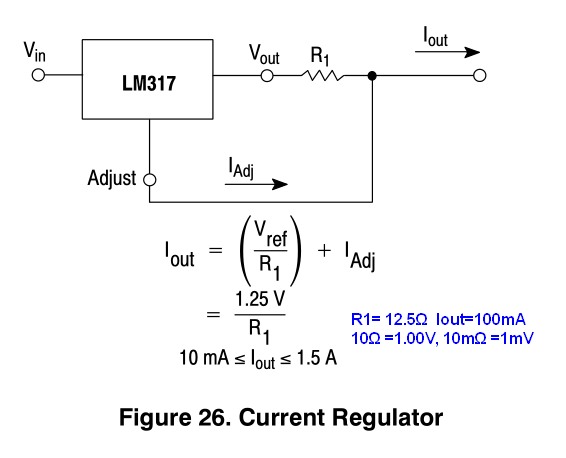

The formula from the TPS73801 datasheet is also here as a jpg. I understood that 1.21V/12.1Ω = 100mA. As the predicted output voltage for the regulator was 5.04V and one is supplying 5.02V, I imagine I have understood that calculation correctly, but don't understand why the current is so high. I used 12.1Ω for R1 and 38Ω for R2.

Any ideas? Is some component like an additional resistor to limit the current missing from this circuit?

Thanks.

The circuit below is not functioning as I'd hoped/expected. This is an experiment making a milli ohmeter, that is the purpose of this circuit; I was unable to breadboard it, or simulate a couple of the ICs, so I just made a prototype to see what would happen, therefore it's very rough and ready.

Are there any obvious mistakes in the design that would cause a predicted 100mA constant current appear to be in fact 2A?

The voltage regulators are supposed to be putting out 5V and 100mA...

- The 73801 which supplies the ICs does output 5.02V, not sure of its current output (yet) as that is not an issue.

- The 73801 which feeds the DUT resistor part of the circuit supplies a poor 1V, and according to the multimeter is blasting out 2.1A down to 1.6A by the time the 555 "Start" pulse ends. Bad for the battery too. I understand this high current is why the output voltage is only 1V, and not 5.02V.

(The 555 "Start button" sends a signal to the 73801 "enable" pin, otherwise the 73801 for the DUT resistor has 0V output).

The formula from the TPS73801 datasheet is also here as a jpg. I understood that 1.21V/12.1Ω = 100mA. As the predicted output voltage for the regulator was 5.04V and one is supplying 5.02V, I imagine I have understood that calculation correctly, but don't understand why the current is so high. I used 12.1Ω for R1 and 38Ω for R2.

Any ideas? Is some component like an additional resistor to limit the current missing from this circuit?

Thanks.