Vermes

Advanced Member level 4

Construction:

The tray was made of a food container. It stands on feet made of a foam pipe insulation. The vibrator is made from a fan. There is some glue between two blades – that makes a pretty good beating during the operation. The fan is glued underneath the tray. There is a temperature sensor (DS1820) in the tray (in a shrink jacket and flooded with an adhesive). The heater is from a pet store.

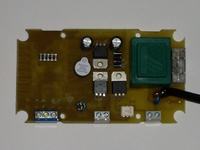

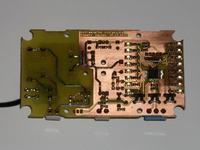

The etching tank is controlled by a microcontroller. It enables setting the temperature and time of etching. It has 2 rows of leds which are used to go through a simple menu. It it steered by 3 microswitches, and it has a buzzer, too.

The heater is steered by a triac.

The vibrator is steered by LM317.

The fan is steered by a potentiometer – the strength of vibrations.

Theory and practice:

- it worked without any driver for few months and there was no breakdown (sometimes the fan-vibrator attached on thermoglue drops)

- the heater worked well too

- the bath is filled with 1 liter of liquid to cover the heater

- at too big vibrations, the 25W heater had problems to heat to the temperature set, therefore it's better to give a smaller fan than the vibrator

- it's better to cover the bath (it splashes)

- the time of etching is 15 minutes and to 30 minutes, when the liquid is used

Link to original thread (with useful attachments) – Wytrawiarka wibracyjna

Last edited: