cupoftea

Advanced Member level 5

Hi,

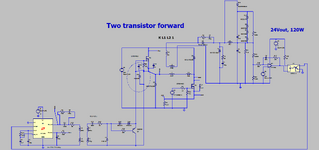

Doing Two Transistor Forward, off Mains FWB. No PFC. 100-265vac. 130Wout, 24Vout, 120kHz.

Np/Ns = 22/12. Sandwich wound. No Fan.

Secondary diodes are STTH5L06D (TO220 metal tab)

The two sec diodes are both side by side and screwed to a flat plate of anodised aluminium of size 15cm x 10cm by 2mm thick.

(OK, its got a 90 degree bend down the middle but lets not go into that).

At 115VAC and full load all is well, all temperatures are below 65degC.

But go up to 240VAC, and the freewheel diode starts getting well hot. Goes to 100 degC within minutes.

Then blew up a bit later...(I hadn't yet thermocoupled it when it first blew up as I thought the alu plate

would be a good "cooler" for it.)

(All with prototype PCB in open lab ambient (22degc))

So I believe the main cause is reverse recovery, also I hadn't expected the alu plate to be so bad as a heatsink.

Are there different types of "aluminium" with differing thermal properties?

This alu "Plate is actually a right angle bracket used to screw the supply into the unit.

It feels rather hard for aluminium.

Also, I notice quite a temperature gradient along it. Hot near FETs... much cooler at ends.

STTH5L06D

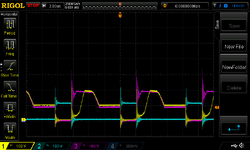

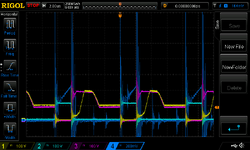

In scopes attached...........("Two tran fwd1" & "Two tran fwd2")

light blue = Freewheel diode volts

Red = Lower fet vds

yellow = Upper fet vds

Darker blue (noisy) = primary current

Also for "Two Tran fwd3" scope shot...

light blue = Power diode volts

yellow = freewheel diode volts

Am actually thinking of parallel SiC diodes, or non-sandwich winding so the leakage-in-sec can staunch the rev rec current....Would you concur?

The voltage reflected to the secondary is so high that this diode is getting "roughed up" by rev rec currents , a bit like like a PFC diode.

Reckon two if these in pllel should do the trick....

Any cheaper ways?

Doing Two Transistor Forward, off Mains FWB. No PFC. 100-265vac. 130Wout, 24Vout, 120kHz.

Np/Ns = 22/12. Sandwich wound. No Fan.

Secondary diodes are STTH5L06D (TO220 metal tab)

The two sec diodes are both side by side and screwed to a flat plate of anodised aluminium of size 15cm x 10cm by 2mm thick.

(OK, its got a 90 degree bend down the middle but lets not go into that).

At 115VAC and full load all is well, all temperatures are below 65degC.

But go up to 240VAC, and the freewheel diode starts getting well hot. Goes to 100 degC within minutes.

Then blew up a bit later...(I hadn't yet thermocoupled it when it first blew up as I thought the alu plate

would be a good "cooler" for it.)

(All with prototype PCB in open lab ambient (22degc))

So I believe the main cause is reverse recovery, also I hadn't expected the alu plate to be so bad as a heatsink.

Are there different types of "aluminium" with differing thermal properties?

This alu "Plate is actually a right angle bracket used to screw the supply into the unit.

It feels rather hard for aluminium.

Also, I notice quite a temperature gradient along it. Hot near FETs... much cooler at ends.

STTH5L06D

In scopes attached...........("Two tran fwd1" & "Two tran fwd2")

light blue = Freewheel diode volts

Red = Lower fet vds

yellow = Upper fet vds

Darker blue (noisy) = primary current

Also for "Two Tran fwd3" scope shot...

light blue = Power diode volts

yellow = freewheel diode volts

--- Updated ---

Am actually thinking of parallel SiC diodes, or non-sandwich winding so the leakage-in-sec can staunch the rev rec current....Would you concur?

The voltage reflected to the secondary is so high that this diode is getting "roughed up" by rev rec currents , a bit like like a PFC diode.

Reckon two if these in pllel should do the trick....

Any cheaper ways?

Attachments

Last edited: