Vermes

Advanced Member level 4

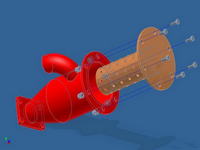

It is a turbine engine based on turbocharger. Combustion chamber should be tested for propan-butan. Some advices how to create such a device, can be found here.

The main input parameters for calculating is the diameter of the radial compressor inlet.

The engine has three installations: oil, fuel (gas) and electrical. The oil installation includes: cooler from Opel Kadett, oil filter with bypass valve form engine of Toyota Avensis, oil tnak, the pump from the compressor K2-150 and manometer. The pump is powered by a modified drill-driver powered from 12V accumulator.

Gas installation consists of 2kg gas tank, manometer, ball valve and nozzle.

Electrical installation consists of ignition coil, the ignition system and ignition spark. Triggering a spark is manual, but it can be based on timer 555.

In the first version, the engine was to make noise. It was also very heavy.

The rotor is mounted on the bearing assemblies. Measurement of the power turbine speed is made by optical sensor.

The measurement of speed of the turbocharger is very difficult. An optical sensor with a diode and photodiode was pasted on the tube mounted near the air inlet.

Due to the fact that implementation of the brake is quite difficult, it is better to connect a car alternator to the turbine rotor.

Turbocharger speed is up to 160 000 rot/min. Note the pressure of gas in the tank. The problem is the rapid cooling of the gas at the expansion, so keep gas tanks in warm water to maintain constant temperature.

Videos:

Link to original thread (useful attachment) – Silnik turbinowy na bazie turbosprężarki