AleXYZ

Junior Member level 3

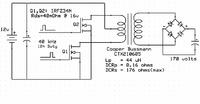

The following circuit is on a breadboard on my bench, it runs at 40 kHz with approximately 10-15% duty cycle. The end goal is to get 170-200 volts in the output as efficiently as possible.

My Question: How do I tune this Push-Pull circuit to get maximum efficiency? As it is now, most of the energy going into the circuit is dissipating out the MOSFETs as heat. (No, I haven't smoked one yet but I did slightly burn a finger.) At a guess I'd say I'm getting 5% efficiency. I am hoping for closer to 90%.

I think all of the relevant component info is in the diagram but if any other details are necessary I'll be happy to provide them.

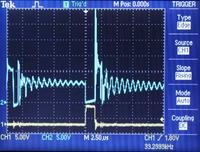

And if it helps, here is a scope image of the gate (yellow) and source (blue) for one MOSFET of the push-pull.

I scoured EdaBoard and Google for posts that might have maths or tuning for this type of circuit but came up empty. Any advice?

---------- Post added at 17:57 ---------- Previous post was at 17:15 ----------

Side Note: I am looking into Royer oscillator configuration as well, however the following document indicates that the direct drive (via PWM) method I am using can be used to achieve higher efficiency. This document, however, does not provide enough detail to do circuit tuning to achieve that efficiency.

https://www.microsemi.com/media/PDoct2004.pdf

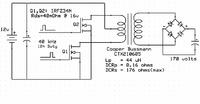

My Question: How do I tune this Push-Pull circuit to get maximum efficiency? As it is now, most of the energy going into the circuit is dissipating out the MOSFETs as heat. (No, I haven't smoked one yet but I did slightly burn a finger.) At a guess I'd say I'm getting 5% efficiency. I am hoping for closer to 90%.

I think all of the relevant component info is in the diagram but if any other details are necessary I'll be happy to provide them.

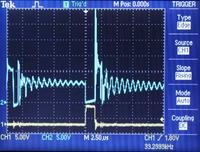

And if it helps, here is a scope image of the gate (yellow) and source (blue) for one MOSFET of the push-pull.

I scoured EdaBoard and Google for posts that might have maths or tuning for this type of circuit but came up empty. Any advice?

---------- Post added at 17:57 ---------- Previous post was at 17:15 ----------

Side Note: I am looking into Royer oscillator configuration as well, however the following document indicates that the direct drive (via PWM) method I am using can be used to achieve higher efficiency. This document, however, does not provide enough detail to do circuit tuning to achieve that efficiency.

https://www.microsemi.com/media/PDoct2004.pdf