JacquesNel

Newbie level 4

Good evening all

I looked through the forum and couldn't find an answer to a problem I'm encountering. If I missed something, I apologize.

I am an electrician, but I work 240V-11kV, and my electronics experience and knowledge are only college-based.

I'm trying to repair a washing machine control board that has previous repair attempts, I dislike guys who insist on replacing the whole board instead of fixing the problem.

The solenoid for the cold water wasn't getting any voltage(required 220-240V) and I tested a bit here and there, from what I can find online the triac supplying the solenoid (4.2Kohm) was faulty, and I couldn't get a like for like replacement, so I replaced it with a BT136 triac, which worked once, the cycle started and I assumed that the problem was solved.

I closed the machine up and then heard the solenoid energizing and de-energizing rapidly without any cycle being started. I tested the voltage on the solenoid I'm getting 160-190v.

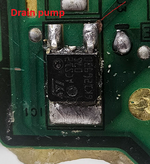

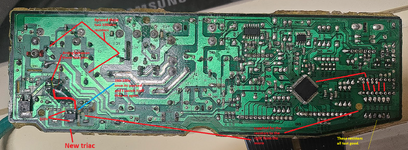

I figured the triac was a dud and replaced it again, the same thing happened. but I also noted a small ark on the pins supplying the one solenoid and the drain pump.

So I figure I'll order the correct part(https://www.mantech.co.za/Stock.aspx?Query=TRIAC+SOT223+600V+1A+5MA+Z3M+iGT=5mAand) and when it comes replace the BT138(https://www.mantech.co.za/ProductInfo.aspx?Item=35M0680) with it and see what happens, the same problem has occurred pulse the drain motor runs as soon as I start a cycle. so the machine will fill and empty itself at the same time.

No error codes from the machine either.

What I'm trying to figure out is what's causing the triacs to pop. I'm a bit lost here, any advice would be much appreciated. please let me know if you need more info

Below are some pictures below for more info.

Thanks in advance guys.

I looked through the forum and couldn't find an answer to a problem I'm encountering. If I missed something, I apologize.

I am an electrician, but I work 240V-11kV, and my electronics experience and knowledge are only college-based.

I'm trying to repair a washing machine control board that has previous repair attempts, I dislike guys who insist on replacing the whole board instead of fixing the problem.

The solenoid for the cold water wasn't getting any voltage(required 220-240V) and I tested a bit here and there, from what I can find online the triac supplying the solenoid (4.2Kohm) was faulty, and I couldn't get a like for like replacement, so I replaced it with a BT136 triac, which worked once, the cycle started and I assumed that the problem was solved.

I closed the machine up and then heard the solenoid energizing and de-energizing rapidly without any cycle being started. I tested the voltage on the solenoid I'm getting 160-190v.

I figured the triac was a dud and replaced it again, the same thing happened. but I also noted a small ark on the pins supplying the one solenoid and the drain pump.

So I figure I'll order the correct part(https://www.mantech.co.za/Stock.aspx?Query=TRIAC+SOT223+600V+1A+5MA+Z3M+iGT=5mAand) and when it comes replace the BT138(https://www.mantech.co.za/ProductInfo.aspx?Item=35M0680) with it and see what happens, the same problem has occurred pulse the drain motor runs as soon as I start a cycle. so the machine will fill and empty itself at the same time.

No error codes from the machine either.

What I'm trying to figure out is what's causing the triacs to pop. I'm a bit lost here, any advice would be much appreciated. please let me know if you need more info

Below are some pictures below for more info.

Thanks in advance guys.