cupoftea

Advanced Member level 6

Hi,

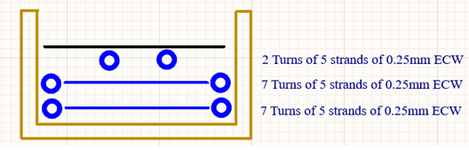

Our 24V input to 24V, 2A 150kHz isolated flyback works fine with the primary wound as two layers

of enamelled copper wire. (PQ20/16 bobbin)

Ns/Np = 15/10

The secondary sandwichs the primary with series windings of 8 turns and 7 turns.(triple insulated wire)

The primary 10 turns are comprised of 2 layers of 5 turns (3 strands of 0.315mm ECW) . We just wind 5 turns across the bobbin,

and then the next 5 gets wound over the top of the previous five turns..its so easy to do it like this -there is no tape between these layers.

I believe that if one layer gets a nick in the enamel then we could be taking a big risk doing this.

I believe that we should really have tape between the layers. Though we have had no problems doing it without tape

for some 2 years.

Do you think we should use tape?

Our 24V input to 24V, 2A 150kHz isolated flyback works fine with the primary wound as two layers

of enamelled copper wire. (PQ20/16 bobbin)

Ns/Np = 15/10

The secondary sandwichs the primary with series windings of 8 turns and 7 turns.(triple insulated wire)

The primary 10 turns are comprised of 2 layers of 5 turns (3 strands of 0.315mm ECW) . We just wind 5 turns across the bobbin,

and then the next 5 gets wound over the top of the previous five turns..its so easy to do it like this -there is no tape between these layers.

I believe that if one layer gets a nick in the enamel then we could be taking a big risk doing this.

I believe that we should really have tape between the layers. Though we have had no problems doing it without tape

for some 2 years.

Do you think we should use tape?