bodewonkinobe

Newbie level 6

Hi all

I am designing an isolated voltage channel within a portable product (a high end portable DMM) which I require 1000V CATII and 600V CATIII rating on the measurement inputs

I am designing to IEC61010.

The product is powered/charged by a DC wall adapter or can be run on its internal batteries.

I am using isolators from analog devices which provide 600V reinforced CATII, but not CATIII

the product has a plastic injection moulded case and some metal BNC/USB ports

In the past I have designed products with metal cases and achieve secondary insulation / protection to bring CATII up to CATIII by using the earth bonding protection as the secondary level of protection.

Now, I need to bring the CATII up to CATII, I cannot rely on the plastic enclosure to add that secondary level of protection, as there are exposed metal parts ….

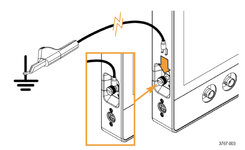

So, bearing in mind that this is a portable device would it be a good approach to achieve a secondary level of protection by including a protective earth terminal on the metal parts, and internally bond any exposed metal parts together and put a clear warning notice on the product that the product must be safety earthed using the terminal (maybe only if the measured voltages exceed the reinforced levels of insulation achieved by the isolators alone?)

Normally the protecting earth is achieved via the wall power adapter, but in this case there isn’t one - is there anything I’m missing here? Or can I just simply add a protective earth terminal and make it clear to the user it must be connected to protective earth in the installation they are measuring if they exceed X voltage ?

Thanks !

I could rephrase the question or summarise it as….

Can I have an earth protection terminal on a handheld product? In order to provide supplementary insulation/protection ?

does it violate any rule I haven’t perhaps caught in my review of iec61010 that says a portable instrument cannot have a protective earth terminal that must be used for X Y and Z situations ?

I am designing an isolated voltage channel within a portable product (a high end portable DMM) which I require 1000V CATII and 600V CATIII rating on the measurement inputs

I am designing to IEC61010.

The product is powered/charged by a DC wall adapter or can be run on its internal batteries.

I am using isolators from analog devices which provide 600V reinforced CATII, but not CATIII

the product has a plastic injection moulded case and some metal BNC/USB ports

In the past I have designed products with metal cases and achieve secondary insulation / protection to bring CATII up to CATIII by using the earth bonding protection as the secondary level of protection.

Now, I need to bring the CATII up to CATII, I cannot rely on the plastic enclosure to add that secondary level of protection, as there are exposed metal parts ….

So, bearing in mind that this is a portable device would it be a good approach to achieve a secondary level of protection by including a protective earth terminal on the metal parts, and internally bond any exposed metal parts together and put a clear warning notice on the product that the product must be safety earthed using the terminal (maybe only if the measured voltages exceed the reinforced levels of insulation achieved by the isolators alone?)

Normally the protecting earth is achieved via the wall power adapter, but in this case there isn’t one - is there anything I’m missing here? Or can I just simply add a protective earth terminal and make it clear to the user it must be connected to protective earth in the installation they are measuring if they exceed X voltage ?

Thanks !

--- Updated ---

I could rephrase the question or summarise it as….

Can I have an earth protection terminal on a handheld product? In order to provide supplementary insulation/protection ?

does it violate any rule I haven’t perhaps caught in my review of iec61010 that says a portable instrument cannot have a protective earth terminal that must be used for X Y and Z situations ?

Last edited: