Vermes

Advanced Member level 4

The spray etching tank can be successfully used for bubble (aeration) or vibration, just apply the appropriate mechanism.

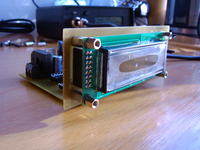

The principle of operation is very simple. The time of etching can be set with an accuracy of one minute. After clicking the OK button, the etching tank waits for heating up the etching liquid to a temperature 40 degrees Celsius. After reaching this temperature, the etching tank starts the engine that will be spraying the liquid on an etched PCB or depending on the application, it will run an aeration pump or vibration engine, you can also adjust the motor speed by a potentiometer. Etching will end after the time specified in the beginning. A digital thermometer DS18B20 from Dallas in housing from transistor TO92 shown in the following picture was used as the temperature sensor.

Elements used:

- housing

- relay x2

- heater

- toroidal transformer 12V/50W

- temperature sensor

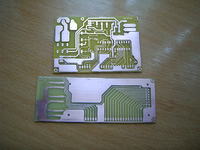

The boards from the attachment in the original thread were mounted and run, they operate correctly. There is no “reset” button in this construction, but in PCB files this button is present, because it may be useful when the process of etching ends and the PCB is not finished yet. Then, by pushing the “reset” button, you can restart the time of the etching.

Files for Eagle with the schema and PCB and files in PDF for thermal transfer are attached in the original thread.

Link to original thread (useful attachment) – Sterownik wytrawiarki natryskowej na Atmega8

Last edited: