bmandl

Full Member level 4

So, I'm designing 3 phase motor soft starter for table saw with phase angle control with SCRs. I'll use 2 reverse parallel SCRs per phase (6 in total). Now, I'm unsure about gate triggering. I've build temp control for a 1 phase heater with TRIAC in the past. In that case, I used a DIAC based optocoupler and mains voltage for gate triggering. But in case of SCR, I'm not sure if I can do the same, or should I use VDD and transistor based optocoupler for gate firing? In latter case, wouldn't microcontroller be exposed if SCR fails and conducts between anode or cathode and gate?

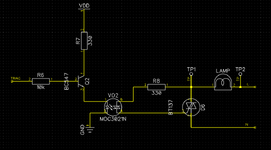

This is circuit, I used with TRIAC:

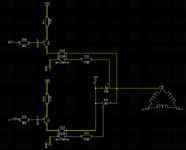

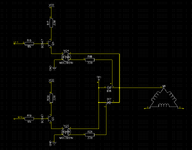

And this is what I'm thinking now for SCR - using same optocoupler and mains voltage (schematic is incomplete - just for one motor winding currently. TP1 is connected to L1):

So my question is: Can I use something like that, or should I use DC voltage for triggering gate of SCR? If so, what additional protection should I use for microcontroller in that case?

This is circuit, I used with TRIAC:

And this is what I'm thinking now for SCR - using same optocoupler and mains voltage (schematic is incomplete - just for one motor winding currently. TP1 is connected to L1):

So my question is: Can I use something like that, or should I use DC voltage for triggering gate of SCR? If so, what additional protection should I use for microcontroller in that case?

Attachments

Last edited: