Shannon_H

Newbie level 3

- Joined

- Mar 17, 2015

- Messages

- 4

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1

- Location

- Moorhead, MN

- Activity points

- 32

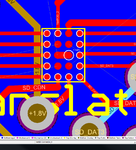

So I've used Altium for a little while for smaller projects (mostly through-hole components) and now I'm delving into surface mount components. When I try to route a 20-Pin Ball Grid Array I can't route the inner 4 pins. The only way I've been able to is by making my traces extremely thin. Is this the only way to get past the outer "wall" of pins or is there something special I should be using?