cupoftea

Advanced Member level 6

Hi,

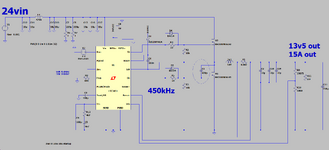

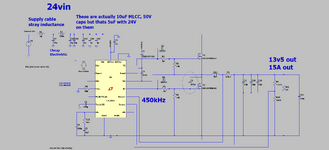

We are doing a Buck as attached (LTspice and PNG) of 24-32Vin, 13v5 out, 15A out and 450kHz.

As can be seen, Our input filter comprises five 10uF,50V,1210 MLCC's and two 220uF, 63V, Alu Electrolytics. (Nichicon UUJ1J221MNJ6MS)

The two 220uF caps at the input are just there for some damping of the input.

As such, there is a total of 6.4A (ACrms) of ripple current at the Buck input.

We want as little of that as possible to be drawn from the 220uF caps, since they

only have 350mA of ripple current rating.

As such, we will place 1Ohm, 2512 resistors in series with them.

Why is it we see our competitors not bothering to do this?

We are doing a Buck as attached (LTspice and PNG) of 24-32Vin, 13v5 out, 15A out and 450kHz.

As can be seen, Our input filter comprises five 10uF,50V,1210 MLCC's and two 220uF, 63V, Alu Electrolytics. (Nichicon UUJ1J221MNJ6MS)

The two 220uF caps at the input are just there for some damping of the input.

As such, there is a total of 6.4A (ACrms) of ripple current at the Buck input.

We want as little of that as possible to be drawn from the 220uF caps, since they

only have 350mA of ripple current rating.

As such, we will place 1Ohm, 2512 resistors in series with them.

Why is it we see our competitors not bothering to do this?