MostlyHarmless

Newbie level 4

Hi All,

Hopefully this is the right place, as this certainly is a Hobby Circuit/Small project issue

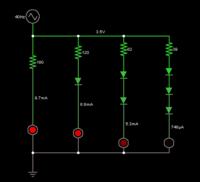

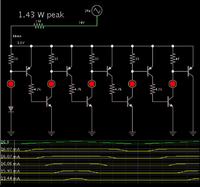

Not sure where to begin. Been trying to figure out how to do circuit for LED's that will take a variable voltage and light up a series of LED's in a progressive way.

I.e I want the LED's to come on when the output voltage goes past certain points. This is for my daughters science project where kids will turn a crank handle connected to a motor, will generate DC voltage. Rather than all the LED's coming on at once, wanted it to appear in stages. I used to do circuit design and messing around with digital and analogue electronics, but alas cannot remember what it is I am looking for or at. For some reason I keep thinking of having like 5 LEDs in an array, then a capacitor feeding the next array (it requiring enough juice to power the 1st array and charge the capacitor enough?) Might be completely wrong

Any pointers gratefully received, hopefully I have explained it right.

R

Hopefully this is the right place, as this certainly is a Hobby Circuit/Small project issue

Not sure where to begin. Been trying to figure out how to do circuit for LED's that will take a variable voltage and light up a series of LED's in a progressive way.

I.e I want the LED's to come on when the output voltage goes past certain points. This is for my daughters science project where kids will turn a crank handle connected to a motor, will generate DC voltage. Rather than all the LED's coming on at once, wanted it to appear in stages. I used to do circuit design and messing around with digital and analogue electronics, but alas cannot remember what it is I am looking for or at. For some reason I keep thinking of having like 5 LEDs in an array, then a capacitor feeding the next array (it requiring enough juice to power the 1st array and charge the capacitor enough?) Might be completely wrong

Any pointers gratefully received, hopefully I have explained it right.

R