octopus dive

Newbie level 5

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

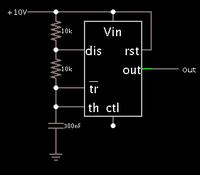

the +10v is from a dc voltage source? but then what do u mean applying a voltage to ctl pin 5?is it that i need to use another voltage source or how??really for asking..it is just a bit confusing when i try to do this in simulation and applying it to hardware