khansaab21

Advanced Member level 4

Three phase inverter trouble

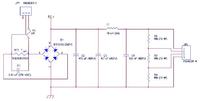

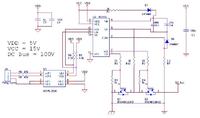

Following is the circuit of single phase of a three phase inverter.

I know I have been around with this circuit (with minor changes) before, but I couldn't help coming here back again with this as I couldn't get it to work. And this time, problem is very weird.

This inverter is working at its best when the DC bus voltage is 12V, output is on DC motors and output frequency is in the range of 0.1-0.5Hz.

But when DC bus voltage = 100 V, a weird thing starts to occur.

Plugging in IGBT's of first phase, every thing stays normal. Plugging in IGBt's of second phase DC bus voltage (being checked directly on the DC bus voltage input connectors) drops to about -500V and varies between -300 to -500V

Plugging in IGBT's of third phase the voltage stabilizes to -300V.

Obviously I cant connect load in this situation. During testings, I have even fried 2 gate drivers and a 4 IGBT's. I need to submit this project early next week. Please, I am in a dire need of help. How to fix this??

Following is the circuit of single phase of a three phase inverter.

I know I have been around with this circuit (with minor changes) before, but I couldn't help coming here back again with this as I couldn't get it to work. And this time, problem is very weird.

This inverter is working at its best when the DC bus voltage is 12V, output is on DC motors and output frequency is in the range of 0.1-0.5Hz.

But when DC bus voltage = 100 V, a weird thing starts to occur.

Plugging in IGBT's of first phase, every thing stays normal. Plugging in IGBt's of second phase DC bus voltage (being checked directly on the DC bus voltage input connectors) drops to about -500V and varies between -300 to -500V

Plugging in IGBT's of third phase the voltage stabilizes to -300V.

Obviously I cant connect load in this situation. During testings, I have even fried 2 gate drivers and a 4 IGBT's. I need to submit this project early next week. Please, I am in a dire need of help. How to fix this??