Vermes

Advanced Member level 4

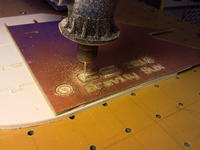

In this project an unusual material was used, which is often used in all kinds of gears and mechanisms for food contact. It was polyethylene PE500 (green) and PE1000 (white). Its features are mainly high stiffness, high abrasion resistance, ease of processing and small price (it can be bought as a waste).

Now few parameters:

- XYZ working area: 180x300x70mm

- max speed (idle): 900mm/min

- spindle speed: 3-30k rpm

- machining capabilities: tested with a special mill 2mm, 1mm recess

- laminate glass: about 100mm/min

- wood: samples in floor panel, which is quite hard up to 150, at 250 the mill broke

- PE500/PE1000: as in the butter, calmly rushes up to 400mm/min

- carbon fiber goes smoothly at 150mm/min but terribly rubbish

- aluminum was also cut, 70mm/min, max 0,5mm recess (unfortunately not very stunning speed)

- polystyrene is milled at full speed, even at 1cm immersion of the mill

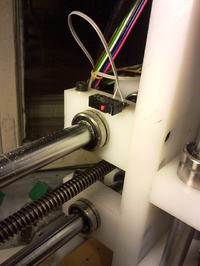

The driver:

Few details:

Link to original thread – Polietylenowa Frezarka CNC v2