xeratule

Member level 4

- Joined

- Apr 4, 2009

- Messages

- 69

- Helped

- 1

- Reputation

- 2

- Reaction score

- 1

- Trophy points

- 1,288

- Location

- Istanbul / TURKIYE

- Activity points

- 1,975

Hi all,

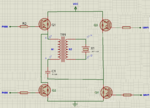

I am designing a driver board to drive piezoelectric crystal (ultrasonic) transducer sensor. I have a well operationg full bridge driver circuit which is driven by 25khz pwm (25khz is the resonance frequency of the transducer). I built a simplified circuit to focus on my problem, please see the attached file:

High power is flowing through high power IGBT while it is triggered by 25khz pwm. The driver circuit is connected to the primary side (N1) of a transformer. Secondary side of the transformer is connected to the transducer (crystal). I'm trying to have maximum active power from the transducer. When I measure the transducer output with impedance analyzer (disconnected from the circuit), at minimum impedance level it seems like 18nf capacitor which has about Xc = 1/ (2*pi*25000hz*18nf) = 350 ohms impedance. So should I have a transformer secondary side which has 350 ohms impedance XL = 2*pi*25000hz*L = 350 ohms which results in L=2.2uH. And If we look at the primary side of the transformer. I have 100nf of capacitor series to it. Should I also keep this side at resonance at 25khz? Xc = X(100nf) = XL(primary)? I think at resonance the reactive power is minimal and active power is at highest value. I am new to resonance and reactive loads so please help me to have an appealing and clear vision.

I actually tried some versions of transformer but couldn't get satisifying results. Sometimes got too few output current, sometimes transformer got too much temprature rise, sometimes got too many output current with unsatisifying power from the transducer.

Welcome to all replies, thanks in advance.

Erhan

I am designing a driver board to drive piezoelectric crystal (ultrasonic) transducer sensor. I have a well operationg full bridge driver circuit which is driven by 25khz pwm (25khz is the resonance frequency of the transducer). I built a simplified circuit to focus on my problem, please see the attached file:

High power is flowing through high power IGBT while it is triggered by 25khz pwm. The driver circuit is connected to the primary side (N1) of a transformer. Secondary side of the transformer is connected to the transducer (crystal). I'm trying to have maximum active power from the transducer. When I measure the transducer output with impedance analyzer (disconnected from the circuit), at minimum impedance level it seems like 18nf capacitor which has about Xc = 1/ (2*pi*25000hz*18nf) = 350 ohms impedance. So should I have a transformer secondary side which has 350 ohms impedance XL = 2*pi*25000hz*L = 350 ohms which results in L=2.2uH. And If we look at the primary side of the transformer. I have 100nf of capacitor series to it. Should I also keep this side at resonance at 25khz? Xc = X(100nf) = XL(primary)? I think at resonance the reactive power is minimal and active power is at highest value. I am new to resonance and reactive loads so please help me to have an appealing and clear vision.

I actually tried some versions of transformer but couldn't get satisifying results. Sometimes got too few output current, sometimes transformer got too much temprature rise, sometimes got too many output current with unsatisifying power from the transducer.

Welcome to all replies, thanks in advance.

Erhan

Attachments

Last edited: