Non-sinusoidal supply current will damage petrol generator?

- Thread starter cupoftea

- Start date

Easy peasy

Advanced Member level 6

The loads determine the current waveshape, mostly, if the inverter output voltage is the " quasi - sine " i.e. stepped square wave about 200V peak then this will influence the current drawn by the loads, however,

if it is sine wave voltage out the loads will entirely determine the current waveshape - up to the current limit of the inverter.

How is it you think the bearings might be affected ?

if it is sine wave voltage out the loads will entirely determine the current waveshape - up to the current limit of the inverter.

How is it you think the bearings might be affected ?

cupoftea

Advanced Member level 6

Thanks, there is no inverter here....just that current coming out of the generator, and going to the loads.

The current to only one load is shown, if there's eight than it'll just be 8x what you see there, because there'll all draw the same current from the generator, and "In phase" with each other.

I had always thought a generator would run smoother if supplying a sinusoidal current in phase with its voltage?

(A motor is like a generator in reverse, and they always say eg a sinusoidal BLDC runs smoother than a trapezoidal one.)

The current to only one load is shown, if there's eight than it'll just be 8x what you see there, because there'll all draw the same current from the generator, and "In phase" with each other.

I had always thought a generator would run smoother if supplying a sinusoidal current in phase with its voltage?

(A motor is like a generator in reverse, and they always say eg a sinusoidal BLDC runs smoother than a trapezoidal one.)

Last edited:

KlausST

Advanced Member level 7

There are two important electrical parameters.We have 240W isolated loads (up to eight at a time) running ultimately from a 3kW, 230vac Petrol generator.

* 3kW is for the motor ...

* and there should be an kVA rating for the generator ... or at least an Amperage rating.

both need to be fulfilled by your power supply

before you wrote there are 8 loads. So are there 8 PFCs or only one. Do all loads switch ON/OFF synchronously or randomly independent?The generator is fed to a Boost PFC then 240 W

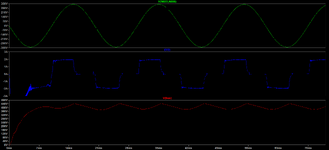

I wonder that the generator voltage is that sinusoidal .. with that non-sinusoidal current. Is both voltage and current from simultaneous sampling?In the attached , green is the generator output voltage (230VAC). Blue is the generator's supplied current.

Red is the Boost "PFC" output voltage. (obviously its not really truly PFC'ing)

****

The motor obviously is a combustion engine ... 4 stroke, one cylinder, thus one explosion every 2 revolutions. This is where "sideways force" is put on the bearings of the motor. I expect this explosion forces much higher than what your load will cause ..Do you think

this will wear out the gennerator's bearings and overheat it?

Additionally the load current causes torque. The torque is not being transferred with the bearing. The bearings get no stress with torque.

It´s the shaft that has to stand the torque and the torque waveform.

I´m not saying that the whole motor-generator is suitable for your load. But I don´t think that bearings in motor or generator are stressed by the waveform of the electrical current.

***

If you are the designer of the (non) PFC: then I recommend to design it a bit more intelligent. I mean you see the output current of the PFC (or even better: you have a signal that gives the "load ON/OFF" signal.) According this signal switch the PFC (duty cycle) ...in a way that you don´t rely on the slow acting feedback of the PFC output capacitor voltage. This way you get a fast change in PFC duty cycle .. resulting in fast switching from low current sine waveform to high current sine waveform ... without undershot or overshot of the PFC output voltage.

Klaus

cupoftea

Advanced Member level 6

Thanks, anything from one to eight loads, and they will switch together. Yes, 8 "PFCs"......I use the "PFC" term loosely becausebefore you wrote there are 8 loads. So are there 8 PFCs or only one. Do all loads switch ON/OFF synchronously or randomly independent?

its more like a fast boost converter than a true Boost PFC.

Thanks, thats the LTspice waveforms...i assume a sinusoidal generator voltage.wonder that the generator voltage is that sinusoidal .. with that non-sinusoidal current. Is both voltage and current from simultaneous sampling?

--- Updated ---

Thanks, yes i believe the best way to do this would be to use a micro to do the PFC and program it optimally....however, we just want to hack it with a cheap BCM PFC chip.......so what we have is a comparator (+ some hysteresis) looking at "pfc" vout, and then the comparator switches it to max power throughput.....(ie, we hacked the "VIN_SENSE" pin so that the BCM chip "thinks" its at mains peak for most of the mains cycle). Also, the comparator switches the voltage on the error amp output COMP pin from min to max, depending on whether the PFC vout is above or below the thresholds.If you are the designer of the (non) PFC: then I recommend to design it a bit more intelligent. I mean you see the output current of the PFC (or even better: you have a signal that gives the "load ON/OFF" signal.) According this signal switch the PFC (duty cycle) ...in a way that you don´t rely on the slow acting feedback of the PFC output capacitor voltage. This way you get a fast change in PFC duty cycle .. resulting in fast switching from low current sine waveform to high current sine waveform ... without undershot or overshot of the PFC output voltage.

This does the job, so i think we will leave it as its cheap......we dont need true "PFC" as its just a lone generator out in a field.

The good thing about a BCM PFC chip is that they have that feature where they reduce the peak current threshold when near the mains zero cross...and we need that as it rings like mad near the zero cross if we dont have that.

So basically, we just hacked up a cheapo BCM PFC chip as it seems to do the job, but we worried about the generator getting somehow damaged as its not a nice sine current.

Last edited:

KlausST

Advanced Member level 7

.i assume a sinusoidal generator voltage.

You really expect a (cheap) generator output to be "ideal"?

Klaus

Easy peasy

Advanced Member level 6

full mechanical ( derived from electrical ) load places the most stress on the bearings. The teeny tiny mech pulsations from any pulsing current are are several orders of magnitude lower - due to flywheel effect of the mech setup.

yongmin capacitor

Junior Member level 2

b不会,这跟电流强度有关,也需要判断发电机的承载极限值

[translated by Google]

No, this is related to the current intensity, and it is also necessary to determine the load limit of the generator

[translated by Google]

No, this is related to the current intensity, and it is also necessary to determine the load limit of the generator

Last edited by a moderator:

Magnethicc

Member level 5

It is not that the current supplied by the generator is not sinusoidal, its that the load consumes non-sinusoidal current.

does the pfc controller IC multiplies the voltage feedback to scale the power demand? if so than what is the issue with doing a simple speed-up circuit to the voltage feedback?

I understand that you are considering the mechanical stresses of this high pulsating current but also take into account what will be the effect of generator output voltage of this very high pulsating current.

does the pfc controller IC multiplies the voltage feedback to scale the power demand? if so than what is the issue with doing a simple speed-up circuit to the voltage feedback?

I understand that you are considering the mechanical stresses of this high pulsating current but also take into account what will be the effect of generator output voltage of this very high pulsating current.

- Joined

- Jan 22, 2008

- Messages

- 53,720

- Helped

- 14,812

- Reputation

- 29,921

- Reaction score

- 14,450

- Trophy points

- 1,393

- Location

- Bochum, Germany

- Activity points

- 303,694

I'd delete the term "PFC" in subsequent discussion. The shown current waveform has nothing to do with PFC, as already conceded.

An AC generator has relevant source impedance (mostly inductive), respectively we can expect a distorted voltage waveform with the assumed current waveform. Asynchronous generators might involve shunt capacitors.

An AC generator has relevant source impedance (mostly inductive), respectively we can expect a distorted voltage waveform with the assumed current waveform. Asynchronous generators might involve shunt capacitors.

cupoftea

Advanced Member level 6

Thanks, in the distortion, what would you expect the peak voltage to be ?

Also, how non-sinusoidal do you believe it will be?

Is this idea of speeding up the "PFC" thus going to be a non-runner?

The high di/dt of the current waveform is obviously going to put voltage spikes i agree into the generators voltage output, due to its inductive nature.

It now seems to me that we are going to have to slow the "PFC" back down and use a big output capacitor bank in it.

What would happen to the generator voltage if we had 3000W's worth of non-PFC'd loads?.....eg, loads that just had a rectifier bridge at the input, going into a smoothing capacitor?

So is it a pre-requisite that one must have "proper" PFC for any load taken from such a small (3kW) generator.?

Also, how non-sinusoidal do you believe it will be?

Is this idea of speeding up the "PFC" thus going to be a non-runner?

The high di/dt of the current waveform is obviously going to put voltage spikes i agree into the generators voltage output, due to its inductive nature.

It now seems to me that we are going to have to slow the "PFC" back down and use a big output capacitor bank in it.

What would happen to the generator voltage if we had 3000W's worth of non-PFC'd loads?.....eg, loads that just had a rectifier bridge at the input, going into a smoothing capacitor?

So is it a pre-requisite that one must have "proper" PFC for any load taken from such a small (3kW) generator.?

Last edited:

Magnethicc

Member level 5

What would I expect the peak voltage to be? no one can tell you that, only experiments. it depends on how much of an inductor the generator really is.

What would happen if you had 3000Ws worth of non-PFC'd load? why even go there? if it breaks in 10 days its ok? if it breaks in 1000 days its ok? just do a good PFC design and be on the safe side.

Look at UCC28070 - when load step occurs the VSENSE drops down and when its too low there is a 100uA current source pushing charge to voltage feedback capacitor, rising its feedback voltage rapidly. You could implement such a mechanism very easily.

also make sure to implement a similar (yet negative in nature) mechanism for when VSENSE rises too high.

What would happen if you had 3000Ws worth of non-PFC'd load? why even go there? if it breaks in 10 days its ok? if it breaks in 1000 days its ok? just do a good PFC design and be on the safe side.

Look at UCC28070 - when load step occurs the VSENSE drops down and when its too low there is a 100uA current source pushing charge to voltage feedback capacitor, rising its feedback voltage rapidly. You could implement such a mechanism very easily.

also make sure to implement a similar (yet negative in nature) mechanism for when VSENSE rises too high.

cupoftea

Advanced Member level 6

Thanks, they should really say in the advert (in the top post) that it can only supply loads with a power factor corrector, i am amazed it doesnt say this.....PFC isnt mandated below 75W, and its entirely conceivable that a customer could plug say thirty 70W , non-PFC'd loads into this generator. When "Joe Bloggs" buys an AC generator, he just thinks that its like a portable mains supply....its obviously nothing remotely like that.

Its all starting to make sense now.

Years ago a company who made non-PFCd amplifiers to plug into the mains

suddenly wanted some PFC'd ones....seemed strange as everything was done as cheap as poss.

But I see now that the point is that when you are running off one of these wee little

generators, you absolutely must do PFC (and properly).

It seems that to use this AC generator, what you really need to do is put a Power Factor corrector after it.....make that give a 400VDC rail...and give that to an inverter which can give a sinusoidal (230VAC) voltage output no matter what current is drawn from it. I think the advert should say...."must also be used with PFC then inverter"....but then again.....if you go ...AC PETROL GENERATOR ---> BOOST PFC --->400VDC.......then why follow that with an inverter?...why not just use the 400VDC as your distribution bus and power your loads from that? Just have sufficient DC fusing.

UCC28070...yes thanks....I ordered 4 of these from a well known disty some years ago for a project.

And all of them were either physically damaged or ESD damaged. The entire project got cancelled

because the whole board had been done for UCC28070 and they didn't want to change it.

____---____----____

The following is a petrol generator into an inverter, and it appears that this is needed if generally available mains-connectable loads are to be connected. So it appears a straightforward generator by itself, cannot be connected to a load , unless of course its purely resistive.

__----__---

In the following they are thorough enough to say that its not suitable for LED lights or general digital equipment. ( of course i assume ot would be if a PFC stage was used)

___---____---___---_

The PG8300A of the top post doesnt seem to have an inverter in with it but is said to be able to supply sensitive electronics loads such as laptops, TVs etc. So how is it this generator can supply this stuff but others need an inverter to do that? Also, the spec says it has an "automatic voltage regulator" in with it, but do you know what this is?....might it actually be an inverter?

PG8300A...

----___---__---__

I asked the question to another AC petrol generator vendor, about whether the generator output needed to be power factor corrected or not , and was told "whats power factor corrected?". I then asked what the waveform was coming out of the generator and they said, that they didnt know, but if i wanted a sine wave output then i had to buy an inverter aswell..........presumably they mean an inverter with a PFC at its front end, but i didnt ask that, because they didnt know what a PFC was.

Its all starting to make sense now.

Years ago a company who made non-PFCd amplifiers to plug into the mains

suddenly wanted some PFC'd ones....seemed strange as everything was done as cheap as poss.

But I see now that the point is that when you are running off one of these wee little

generators, you absolutely must do PFC (and properly).

It seems that to use this AC generator, what you really need to do is put a Power Factor corrector after it.....make that give a 400VDC rail...and give that to an inverter which can give a sinusoidal (230VAC) voltage output no matter what current is drawn from it. I think the advert should say...."must also be used with PFC then inverter"....but then again.....if you go ...AC PETROL GENERATOR ---> BOOST PFC --->400VDC.......then why follow that with an inverter?...why not just use the 400VDC as your distribution bus and power your loads from that? Just have sufficient DC fusing.

UCC28070...yes thanks....I ordered 4 of these from a well known disty some years ago for a project.

And all of them were either physically damaged or ESD damaged. The entire project got cancelled

because the whole board had been done for UCC28070 and they didn't want to change it.

____---____----____

The following is a petrol generator into an inverter, and it appears that this is needed if generally available mains-connectable loads are to be connected. So it appears a straightforward generator by itself, cannot be connected to a load , unless of course its purely resistive.

P1 1000W / 1kW Petrol Inverter Suitcase Generator, Lightweight & Quiet Running with DC & USB Outputs | P1000i

The P1000i powered by a 4-stroke engine, is lightweight silenced inverter generator ideal for motorhome and caravan use. Shop this suitcase generator now!

__----__---

In the following they are thorough enough to say that its not suitable for LED lights or general digital equipment. ( of course i assume ot would be if a PFC stage was used)

The PG8300A of the top post doesnt seem to have an inverter in with it but is said to be able to supply sensitive electronics loads such as laptops, TVs etc. So how is it this generator can supply this stuff but others need an inverter to do that? Also, the spec says it has an "automatic voltage regulator" in with it, but do you know what this is?....might it actually be an inverter?

PG8300A...

----___---__---__

I asked the question to another AC petrol generator vendor, about whether the generator output needed to be power factor corrected or not , and was told "whats power factor corrected?". I then asked what the waveform was coming out of the generator and they said, that they didnt know, but if i wanted a sine wave output then i had to buy an inverter aswell..........presumably they mean an inverter with a PFC at its front end, but i didnt ask that, because they didnt know what a PFC was.

Last edited:

cupoftea

Advanced Member level 6

Can you confirm that to charge up a laptop from a standard laptop power supply from the PG8300A (petrol generator of the top post) would mean having...

PG8300A-->PFC-->400VDC-->Isolating converter-->400VDC-->Mains inverter-->Laptop power supply-->Laptop

?

PG8300A-->PFC-->400VDC-->Isolating converter-->400VDC-->Mains inverter-->Laptop power supply-->Laptop

?

- Joined

- Jan 22, 2008

- Messages

- 53,720

- Helped

- 14,812

- Reputation

- 29,921

- Reaction score

- 14,450

- Trophy points

- 1,393

- Location

- Bochum, Germany

- Activity points

- 303,694

I didn't hear anyone saying that a 3 KW generator can't drive the discussed load. Some assumptions, e.g. about undistorted sine voltage waveform are unrealistic, but the generator won't necessarily deny operation. Expectable Irms is slightly below maximal rating. As explained, it's unlikely to get relevant mechanical effect of harmonic current.

Small generators are rarely supplied with detailed specs for performance with nonlinear loads, e.g. non-PFC VFD. My experience tells, they generally work, but useable output power may be lower than expected according to kVA spec, e.g. because voltage regulation doesn't work as well as with linear load. Thus practical tests are strongly suggested.

Small generators are rarely supplied with detailed specs for performance with nonlinear loads, e.g. non-PFC VFD. My experience tells, they generally work, but useable output power may be lower than expected according to kVA spec, e.g. because voltage regulation doesn't work as well as with linear load. Thus practical tests are strongly suggested.

KlausST

Advanced Member level 7

No one said so.they should really say in the advert (in the top post) that it can only supply loads with a power factor corrector, i am amazed it doesnt say this

I agree.As explained, it's unlikely to get relevant mechanical effect of harmonic current.

Another information about mechanical "vibrations".

Elecrically: the power(t) = P(t) = V_(t) x I(t)

on a one phase machine ... even on a perfect sine voltage and sine current .. the waveform of power is also sine. Sine with twice the frequency. On a perfectly resisitive load the sine goes from zero to 2x the average power.

Mechanically: P(t) = 2 * Pi * RPM / 60 * torque

since (2 * Pi * RPM / 60) is a constant value ... the torque is directly proportional to power.

Now since the electrical power(t) "ripples" with twice the voltage_frequency .. the torque(t) also ripples with this frequency.

This is true for the generator, and for single phase machines. ..and for sure some of the ripple will be attenuated by the rotational inertia.

*****

No one wants this rippeling of the torque ... thus they invented the three phase generator machine. Where the ripple of the three (shifted) phases "add" .. they add to a perfectly straight flat line. No ripple in electrical power(t), --> no ripple in torque(t). .. ideally.

--> see https://www.electricalpaathshala.com/why-three-phase-power-only/

Klaus

cupoftea

Advanced Member level 6

Thanks,

If you look at the following range of petrol generators.....

Some are called "petrol generators" and some are called "petrol inverter generators".

Its confusing as to exactly what can and cant be powered by each one?

_____---______________________________

REVIEW ON CLARKE WEBSITE

"Disappointed with this generator - would have expected it to be clearer that a 3.4kw Genny (clarke-ig3500af-34kw-open-frame-inverter-gener) can't necessarily power a 1.8kw device (pressure washer). Not all of us are experts - Why not have a drop-down function when choosing a generator that helps customers to make appropriate choices for what application they intend to use the generator for - so they can select the correct Genny from the wide range available? That would be useful customer service."

......Reply from Machine Mart

Hi Philip,We are sorry, that bought the wong generator for your pressure washer. As you say there are many different types of generators. We have created a comprehensive buyer's guide here:https://www.machinemart.co.uk/expert-advice/generators-buyers-guide/ which you may find useful. For any other queries, please consult store staff or our technical team.Many thanks,MM

____-----______________________________

So in the above, why could the "clarke-ig3500af-34kw-open-frame-inverter-generator" not power his pressure washer?

Supposing i take a PG8300A to power my high power bass guitar amp for a concert in a field....will it work?...how would i know?

___---________________________________---

Heres the cheapest petrol generator on the site.....any examples of what it won't be able to power?

---------_____-------___________________________

And for all the so-called "petrol inverter generators", are they all built as follows...?....

Petrol Generator-->PFC-->400VDC-->Isolating converter-->400VDC-->Mains inverter-->

If you look at the following range of petrol generators.....

Single Phase Generators - Machine Mart

Shop our range of single phase generators designed to keep you powered up. Choose from both petrol and diesel single phase generators to find the right one for you.

Some are called "petrol generators" and some are called "petrol inverter generators".

Its confusing as to exactly what can and cant be powered by each one?

_____---______________________________

REVIEW ON CLARKE WEBSITE

"Disappointed with this generator - would have expected it to be clearer that a 3.4kw Genny (clarke-ig3500af-34kw-open-frame-inverter-gener) can't necessarily power a 1.8kw device (pressure washer). Not all of us are experts - Why not have a drop-down function when choosing a generator that helps customers to make appropriate choices for what application they intend to use the generator for - so they can select the correct Genny from the wide range available? That would be useful customer service."

......Reply from Machine Mart

Hi Philip,We are sorry, that bought the wong generator for your pressure washer. As you say there are many different types of generators. We have created a comprehensive buyer's guide here:https://www.machinemart.co.uk/expert-advice/generators-buyers-guide/ which you may find useful. For any other queries, please consult store staff or our technical team.Many thanks,MM

____-----______________________________

So in the above, why could the "clarke-ig3500af-34kw-open-frame-inverter-generator" not power his pressure washer?

Supposing i take a PG8300A to power my high power bass guitar amp for a concert in a field....will it work?...how would i know?

Heres the cheapest petrol generator on the site.....any examples of what it won't be able to power?

And for all the so-called "petrol inverter generators", are they all built as follows...?....

Petrol Generator-->PFC-->400VDC-->Isolating converter-->400VDC-->Mains inverter-->

Last edited:

KlausST

Advanced Member level 7

I guess the terminology is clear:Some are called "petrol generators" and some are called "petrol inverter generators".

The one is a true and simple, traditional AC generator

The other is a generator (most probably .. generating DC somehow) then using a semiconductor inverter to control frequency and voltage

.. because a pressure washer draws a lot more inrush current.can't necessarily power a 1.8kw device (pressure washer).

I see no reason to blame a generator ... when the load draws overly high inrush current.

I don´t see the need for an internal PFC. It is up to the manufacturer to decide the this.And for all the so-called "petrol inverter generators", are they all built as follows...?....

Petrol Generator-->PFC-->400VDC-->Isolating converter-->400VDC-->Mains inverter-->

I don´t see the need for additional internal isolation

(I rather guess the true generator is optimized for generating DC .. (a multi pole generator with rectifier) like in a car)

Klaus

- Joined

- Jan 22, 2008

- Messages

- 53,720

- Helped

- 14,812

- Reputation

- 29,921

- Reaction score

- 14,450

- Trophy points

- 1,393

- Location

- Bochum, Germany

- Activity points

- 303,694

Complaints about generators not being able to power certain equipment haven't much to do with the original thread question. "Inverter" generators have the advantage of supplying stable frequency and voltage over full load range, dynamic overload capability is most likely critical compared to a simple AC machine, particularly inrush current. Behaviour with nonlinear load isn't completely predictable.

cupoftea

Advanced Member level 6

Thanks, but so very few general household loads and even industrial loads need highly stable frequency and voltage. Loads of the petrol generators come with inverters. It seems to me that in the vast majority of cases this is over-engineering surely?"Inverter" generators have the advantage of supplying stable frequency and voltage over full load range, dynamic overload capability is most likely critical compared to a simple AC machine, particularly inrush current. Behaviour with nonlinear load isn't completely predictable.

Granted though that eg motors with high startup inrush wont be able to start through an inverter which would presumably be current limited.

It sounds to me that the marketing people are shipping petrol generators with inverters for no good reason, other than to play on the public's fear that their load wont be use-able from a plain petrol generator.

It seems to me that any petrol generator can supply most loads other than high-start-up-inrush-current-motors.....and certainly does not need an inverter....though as discussed, strangely, most petrol generators come with an inverter.

The other disadvantage of having an inverter is that they have high standby power......after all, they have a big AC output cap which is getting charged/discharged from +325V to -325V every 10ms. Not only that, but for a single phase petrol generator.....the inverter is virtually certain to be preceeded by a Boost PFC stage...meaning more losses.

But as you allure, it looks like where an inverter is included with the petrol generator, its just because having an inverter there is literally the best way to implement overcurrent limiting......seems crazy to have to shovel a whole inverter in there just for that....but so it is. Of course, the inverter does not at all have to be a true sinusoid inverter in order to implement current limiting.......so it looks to me that there's a lot of over-engineering going on here in terms of shovelling a full sinusoidal inverter in with a petrol generator....but the marketeers probably guess that most individuals purchasing a petrol generator are not short of money, and so can be lulled into shelling out for a full sinusoidal inverter aswell. They can put it in the garage alongside their gold plated audio connectors and the "magic capacitor units" which make your electricity bill come to zero.

Last edited:

Similar threads

-

Why use Pure sinusoidal inverters for off-grid "mains" supply?

- Started by cupoftea

- Replies: 4

-

-

-

-