stube40

Member level 3

- Joined

- Feb 10, 2010

- Messages

- 55

- Helped

- 4

- Reputation

- 8

- Reaction score

- 4

- Trophy points

- 1,288

- Location

- Queensland, Australia

- Activity points

- 1,825

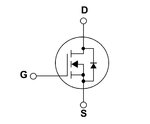

Alot of MOSFETs come with a built-in diode across the source and drain. The attached diagram outlines what I mean. I would like to confirm that the purpose of this diode is to allow the MOSFET to handle reverse current to flow.

I know this question might sound really dumb, but I'm not an electronics expert.

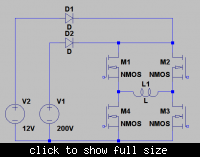

Further, if this is indeed the case, is it possible to exploit this diode to enable the MOSFET to allow reverse current in an application where we expect regular reverse currents?

Finally, which particular parameters in the data sheet for a MOSFET describe the diode's maximum reverse current and how long it can maintain this current for?

I know this question might sound really dumb, but I'm not an electronics expert.

Further, if this is indeed the case, is it possible to exploit this diode to enable the MOSFET to allow reverse current in an application where we expect regular reverse currents?

Finally, which particular parameters in the data sheet for a MOSFET describe the diode's maximum reverse current and how long it can maintain this current for?