lunatic_ash

Newbie

Hi guys.

I bought a brand new Telefunken U47 microphone in April 2024

I had used it with no problem, but a few days ago, a slight but noticeable hum noise occurred around 120Hz.

you can see the EQ image here in the picture

I googled and found a similar case. Someone said it's an electrolytic caps problem in the power supply.

https://repforums.prosoundweb.com/index.php?topic=23670.0

I'm not gonna repair it by myself, but really want to know what the problem is.

I've already sent an email to Telefunken, but still waiting.

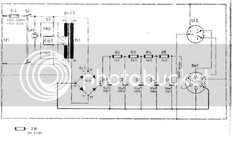

I took a picture of the inside of PSU, and you can see here

Can you guys tell me which parts function as filters? (someone told me to check the brown ones, but not sure about it cause I'm a totally layman)

I want to replace them with exactly the same model, and I think I need to order before visiting a repair shop.

I bought a brand new Telefunken U47 microphone in April 2024

I had used it with no problem, but a few days ago, a slight but noticeable hum noise occurred around 120Hz.

you can see the EQ image here in the picture

I googled and found a similar case. Someone said it's an electrolytic caps problem in the power supply.

https://repforums.prosoundweb.com/index.php?topic=23670.0

I'm not gonna repair it by myself, but really want to know what the problem is.

I've already sent an email to Telefunken, but still waiting.

I took a picture of the inside of PSU, and you can see here

Can you guys tell me which parts function as filters? (someone told me to check the brown ones, but not sure about it cause I'm a totally layman)

I want to replace them with exactly the same model, and I think I need to order before visiting a repair shop.

Last edited by a moderator: