Pixelx

Member level 1

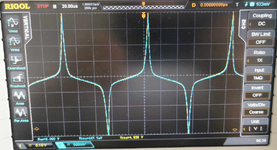

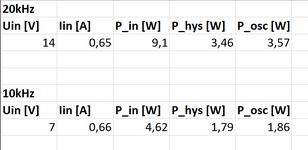

Hello, I designed an H-bridge for testing magnetic materials in transformers. Current is measured using a 1:250 transformer with a 22ohm measuring resistor + 470pF in parallel on secondary side. Current transformer time constant 6.53ms. The magnetization error in relation to the main current is 0.25%.

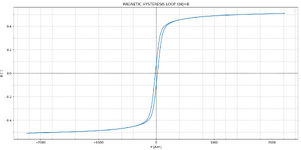

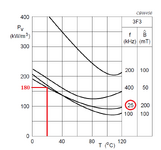

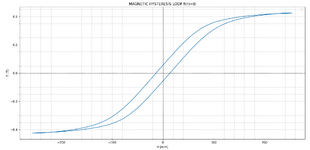

The hysteresis loop I received for 10kHz is for a square signal (voltage) and "triangular" current in the datasheet, induction B = 440mT and current H = 1200A/m are for sine, I received 490mT for 1200A/m

Other data:

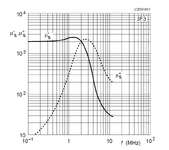

Core: E32/16/9-3F3 FERROXCUBE

Al: 2300nH

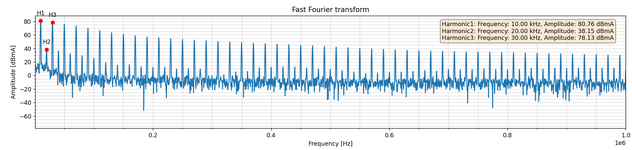

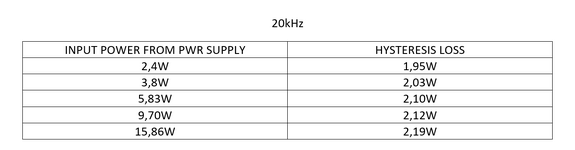

I obtained hysteresis losses of 1.81W for a non-sinusoidal signal (large number of harmonics)

Hysteresis loss per cycle: 29.31 J/m³

Frequency 10kHz

RMS current 11.74A

PEAK 41.31A

N_prim = 4

N_sec = 20

L_prim = 40 uH

le = 74mm

Ae = 83 mm2

Ve = 6180 mm3

What do you think about these results about Hc and Br, hysteresis losses and B and H, are they correct?

The hysteresis loop I received for 10kHz is for a square signal (voltage) and "triangular" current in the datasheet, induction B = 440mT and current H = 1200A/m are for sine, I received 490mT for 1200A/m

Other data:

Core: E32/16/9-3F3 FERROXCUBE

Al: 2300nH

I obtained hysteresis losses of 1.81W for a non-sinusoidal signal (large number of harmonics)

Hysteresis loss per cycle: 29.31 J/m³

Frequency 10kHz

RMS current 11.74A

PEAK 41.31A

N_prim = 4

N_sec = 20

L_prim = 40 uH

le = 74mm

Ae = 83 mm2

Ve = 6180 mm3

What do you think about these results about Hc and Br, hysteresis losses and B and H, are they correct?

Attachments

Last edited: