H2M

Member level 1

Hi

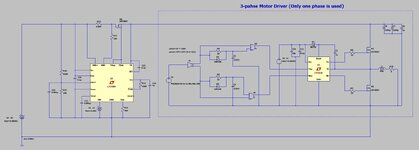

I'm trying to design a 3-phase motor driver. I want to have over current protection in my design, so I have used LTC7000 in order to have over current protection in my bus line. the problem is I can't raise the MOSFET current (Load Current) above 10 Amps! with any shunt resister LTC7000 will turn off the MOSFET when current reach above 10 Amps. Can anybody help me? I attached below my LTspice simulation.

I'm trying to design a 3-phase motor driver. I want to have over current protection in my design, so I have used LTC7000 in order to have over current protection in my bus line. the problem is I can't raise the MOSFET current (Load Current) above 10 Amps! with any shunt resister LTC7000 will turn off the MOSFET when current reach above 10 Amps. Can anybody help me? I attached below my LTspice simulation.