CB33

Newbie level 5

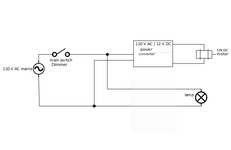

I have a technical question regarding a light fixture I'm building that also has a motor in it. I have geometric shapes that spin slowly around the light fixture light bulbs (almost like a mobile) and this is what I'm using the motor for. The light fixture will be attached to the ceiling like any normal light fixture or chandelier and I want to use a light switch on the wall to be able to turn it on and off. To power the light bulbs and the motor I am using an Inverter which is 12 Volt DC To 110 Volt AC. When you turn the light switch on both the light bulbs will turn on as well as the motor. The question I have is in regards to a dimmer switch. I want to use a dimmer switch to be able to make the lighter brighter or dimmer. However, because the motor is also being controlled by the dimmer switch I want to know if this will be a problem and what will happen. Will it slow down the rotation? Will It damage the motor? If it will pose a problem are there any simple solutions? The motor I'm using is a 12V Synchronous DC geared 1 RPM motor using AC power supply. Any insight or suggestion would be greatly appreciated.

Also, on a side note I'm not sure what inverter I should use for this project. The choice is between a constant current inverter/driver vs constant voltage inverter/driver. I'm not sure which one to use here. Thank you!

Also, on a side note I'm not sure what inverter I should use for this project. The choice is between a constant current inverter/driver vs constant voltage inverter/driver. I'm not sure which one to use here. Thank you!