simce

Full Member level 4

Hi,

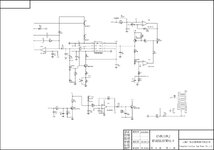

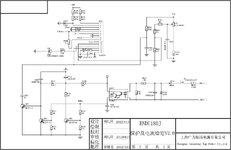

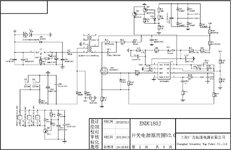

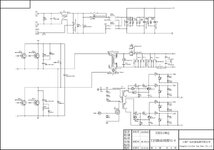

I'm looking for welder control module pin description and if possible schematic of the module from attached picture. The welder is currently overshooting set current and on currents below 90A the output current is not steady but fluctuates quite significantly. This "behavior" is seen even when the welder was new, but now i'm getting annoyed since I'm having difficulties weld thin metal.

I'd like to get information how control board operates and hopefully disable hot start and force arc features which i believe are making the issues.

Thanks.

I'm looking for welder control module pin description and if possible schematic of the module from attached picture. The welder is currently overshooting set current and on currents below 90A the output current is not steady but fluctuates quite significantly. This "behavior" is seen even when the welder was new, but now i'm getting annoyed since I'm having difficulties weld thin metal.

I'd like to get information how control board operates and hopefully disable hot start and force arc features which i believe are making the issues.

Thanks.