boylesg

Advanced Member level 4

- Joined

- Jul 15, 2012

- Messages

- 1,023

- Helped

- 5

- Reputation

- 10

- Reaction score

- 6

- Trophy points

- 1,318

- Location

- Epping, Victoria, Australia

- Activity points

- 11,697

I have just had an idea.....

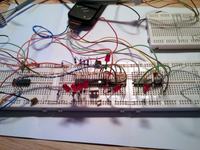

Take these things, cut them in half and solder the pieces in strategic positions on the prototype solder boards to form non-solder junctions specific to a particular type of circuit e.g. MC34063A step up converter.

You could easily change components around without messing up the copper eyelets by continually re-soldering them.

You could fit a slightly wider range of wire gauges in these spring loaded contacts and they would held fairly firmly compared the machined type IC sockets and bread boards.

You could easily just mount the boards in the enclosures and not bother permanetly soldering the components, thus allowing you to vary the components at any time in the future.

I wouldn't be particularly practical to try and do this with breadboards.

Unless you can get these types of IC sockets as strips. But so far I have only found the machined type ones with the circular holes in strips

Take these things, cut them in half and solder the pieces in strategic positions on the prototype solder boards to form non-solder junctions specific to a particular type of circuit e.g. MC34063A step up converter.

You could easily change components around without messing up the copper eyelets by continually re-soldering them.

You could fit a slightly wider range of wire gauges in these spring loaded contacts and they would held fairly firmly compared the machined type IC sockets and bread boards.

You could easily just mount the boards in the enclosures and not bother permanetly soldering the components, thus allowing you to vary the components at any time in the future.

I wouldn't be particularly practical to try and do this with breadboards.

Unless you can get these types of IC sockets as strips. But so far I have only found the machined type ones with the circular holes in strips