syazelle

Newbie level 2

Hello,

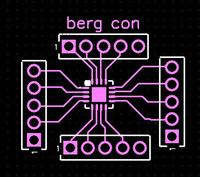

I got some questions regarding the test jig. If I'm well informed, a test jig is used to verify the connections between components on an IC or carry out continuity test, or testing the microcontroller or maybe resistance testing.

I woud like to know, how is it possible to design a test jig that can do all of the tests mentioned above?

I'm working on an intern project on designing a test jig for an electonic board. The problem is I don't know how to start and what should I do at the first place.

Maybe some one could give me a proper string so i can google the docs required.

Thanks.

I got some questions regarding the test jig. If I'm well informed, a test jig is used to verify the connections between components on an IC or carry out continuity test, or testing the microcontroller or maybe resistance testing.

I woud like to know, how is it possible to design a test jig that can do all of the tests mentioned above?

I'm working on an intern project on designing a test jig for an electonic board. The problem is I don't know how to start and what should I do at the first place.

Maybe some one could give me a proper string so i can google the docs required.

Thanks.