Vermes

Advanced Member level 4

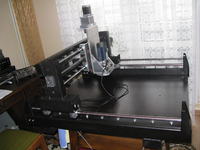

Designed for: milling in wood

Type of construction: construction of welded steel profiles 80x100mm, 40x100, 50x100

Working field: 550mm in x-axis, 650mm in y-axis, 130mm in z-axis

Guides: rollers fi20 on x-axis, fi20 on y-axis, fi16 on z-axis

Drive: trapezoidal screw TR18x4, two nuts on one axle

Motors: stepper motors 3x3 Nm

Electronic control: drivers TA8435 LEOO, motherboard OTTOP

Spindle: Budget

Overall dimensions: width 1000mm, height 780mm, depth 1000mm

Weight: about 70kg

And an additional rotation axle.

Project:

Realization:

Motor controllers, power supply, voltage and current indicator:

Things made on this machine:

Link to original thread – DIY moja maszyna CNC od projektu do wykonania