Kajunbee

Advanced Member level 1

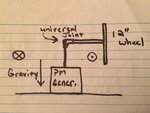

I'm sure most of have seen the demonstration of precession where a spinning wheel remains vertical when only supported by a rope on one side. My question is about the speed of precession around the rope. Most demonstrations I have seen it is relatively slow. From what I've seen there are two things that will increase the rate of precession. Either the wheel slowing down or hanging a counterweight on the other side of wheel. My first question is about the amount of torque generated as the wheel slowly rotates around the rope. If I were to grab the rope where it is attached to wheel axle would it be easy to stop the precession. Or would the gyroscope react to the resistance and try to maintain its rate of precession by increasing torque.

This may be something I have to experiment with on my own but if anyone has any knowledge they can share it would be appreciated.

This may be something I have to experiment with on my own but if anyone has any knowledge they can share it would be appreciated.