kbsanjayvasanth

Newbie level 4

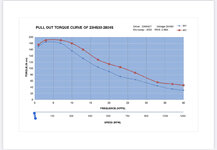

Hi! For my experiment, I am trying to fluctuate (front and back motion) a 3-D printed airfoil using a stepper motor with the capability of 1000RPM (and I use 999 RPM forward and 999 backward) but I'm not getting the desired frequency. This is with a water flow of 50 liters per minute flowing over the airfoil. The max frequency I'm getting is 3Hz. What could be the reason for this? I'm from Aerospace bg so not too familiar with complicated electronic problems. My initial guess is because of the inertia of the rotor in this case. Please correct me if I am wrong.

I have attached a link to the motor that I am using with a stepper motor controller. Stepper motor

Stepper motor controller

Any suggestions could help!

I have attached a link to the motor that I am using with a stepper motor controller. Stepper motor

Stepper motor controller

Any suggestions could help!