T

treez

Guest

Hi,

A contractor has presented us with some schematics of SMPS’s that he says he’s done at previous companies. He is offering to re-use them, since they are very cheap in terms of low parts count.

These include Offline, 240VAC DCM and BCM Flyback SMPS’s to 125W with vout = 25v.

They also include offline , 240VAC, 1 Transistor forward converters up to 150W.

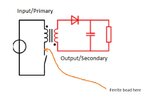

They all have ferrite beads in the drain of the primary switching FET (as attached). Would you agree with me that this is a very poor situation?

I mean, surely, if the drain di/dt is wanting to be reduced, then surely one would increase the series gate resistor? (or is it that the FET may go obsolete, and then the series gate resistor would need value tuning again, so having a ferrite bead there prevents this re-tuning needing to be done?...thats the only reason I can think of to put a ferrite bead in this place.)

Another point is that having a ferrite bead here means you’re breaking an inductive current when the FET switches off…so the FET drain voltage will shoot up higher.

Another point is that Flybacks and forwards have some leakage inductance which is "seen" by the fet as it switches on...so why bother adding a ferrite bead aswell? Isnt this ferrite bead, in this position, simply a throw-back to the old days where CCM boost PFC's only had slow diodes to work with, and some way had to be found to reduce the reverse recovery current spike...that antique SMPS situation is the only one that i can think of where such ferrite beads were warranted?

However, it does occur to me, that as mad as this component is, just maybe, these nice, cheap SMPS’s won’t work on max load if we simply short out this ferrite bead? I mean, due to the lack of other measures to reduce di/dt, these power supplies now rely on this dodgy ferrite bead to reduce FET drain di/dt…just maybe if we short these ferrite beads out then increased noise will get into the control and the power supplies will mal-function.

Isnt a bit like getting up to the top of Mount Everest, opening your lunchbox, and finding that all that’s in there is moldy bread , but having to eat it anyway because you’ll starve if you don’t?

A contractor has presented us with some schematics of SMPS’s that he says he’s done at previous companies. He is offering to re-use them, since they are very cheap in terms of low parts count.

These include Offline, 240VAC DCM and BCM Flyback SMPS’s to 125W with vout = 25v.

They also include offline , 240VAC, 1 Transistor forward converters up to 150W.

They all have ferrite beads in the drain of the primary switching FET (as attached). Would you agree with me that this is a very poor situation?

I mean, surely, if the drain di/dt is wanting to be reduced, then surely one would increase the series gate resistor? (or is it that the FET may go obsolete, and then the series gate resistor would need value tuning again, so having a ferrite bead there prevents this re-tuning needing to be done?...thats the only reason I can think of to put a ferrite bead in this place.)

Another point is that having a ferrite bead here means you’re breaking an inductive current when the FET switches off…so the FET drain voltage will shoot up higher.

Another point is that Flybacks and forwards have some leakage inductance which is "seen" by the fet as it switches on...so why bother adding a ferrite bead aswell? Isnt this ferrite bead, in this position, simply a throw-back to the old days where CCM boost PFC's only had slow diodes to work with, and some way had to be found to reduce the reverse recovery current spike...that antique SMPS situation is the only one that i can think of where such ferrite beads were warranted?

However, it does occur to me, that as mad as this component is, just maybe, these nice, cheap SMPS’s won’t work on max load if we simply short out this ferrite bead? I mean, due to the lack of other measures to reduce di/dt, these power supplies now rely on this dodgy ferrite bead to reduce FET drain di/dt…just maybe if we short these ferrite beads out then increased noise will get into the control and the power supplies will mal-function.

Isnt a bit like getting up to the top of Mount Everest, opening your lunchbox, and finding that all that’s in there is moldy bread , but having to eat it anyway because you’ll starve if you don’t?