Vermes

Advanced Member level 4

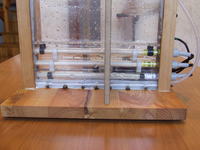

It is a conventional etching tank equipped with a flat aquarium with aeration and heaters. The enclosed heaters are along with temperature sensor and there is no loose elements nor cables inside. Plastic grille was mounted to prevent falling the plate between the heaters. A compressor assembled from a refrigerator unit was used to aeration that guarantees the bath motion. The container was done with the plexiglass. The whole was equipped with an electronic thermostat with timer and buzzer.

Construction

The container was made of 3 strips cut from 5mm thick plexiglass (bottom and sides), to which two rectangular plated 235mm x 345mm x 2,2mm are attached. The whole was bolted on the ordinary sanitary silicone by 50 screws. 3 large holes are made in one of the strip sides for heaters and the 2 smaller ones for the sensor in the heat shrink tubing and aeration hose. The tubing is inserted into the hole and clamped by a rigid tube. Additionally, the tubing was perforated with a needle. The holes are so small that without the check valve, water appears in outer parts after several minutes. An ordinary aquarium air pump is not able to press air through such small holes, that is why the compressor was used. Heaters (2x100W + 90W) are pressed into the holes on the original elastic bands and on the inside they are additionally sealed with silicone. Glass ends of the heaters come in wells drilled in the opposite strip, so that they are rigidly mounted and do not move. Thermal expansion of the glass housings is compensated by soft rubber mount. To the top of the heater on the original hooks there is a nicked plexiglass grid fastened, that prevents the tiles from falling between the heater. The container was reinforced with wooden sides. The container was vertically glued on the silicone to a painted base (260mm x 185mm x 18mm). Lower edges were glued with vicol. On one side electronics were mounted in a wooden casing with aluminum panel. To stiffen the assembly of the container and plexiglasss walls that bend under the influence of liquid, two cropped at the top at an angle hdf plates were vertically screwed. Four rubber feet were screwed to the underside of the base, so the whole does not slip and will not scratch the table surface. The etching tank can be easily carried by holding the base of edge of plexiglass container not bothering the strength.

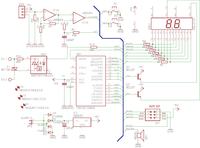

Electronic thermostat with timer

The electronic system based on Attiny2313 microcontroller in SMD version. It is responsible for:

- multiplex control of two LED displays

- support for 2 buttons

- switching on and off the heaters

- starting the sound signal

- analog-digital converter supporting temperature sensor built with PWM converter and an external operational amplifier

Operation

Empty device weighs 1840g, its maximum capacity is 1,5 liters. The optimal amount of solution (1,3 liters) warms up one degree in about 29 seconds. After switching the system, there is the current temperature of the solution shown on the display. With the flashing, system tells us about the reaction of the heaters. Pressing both buttons at once results in turning into the timer setting mode. The first is to add, the second – to subtract the number of minutes. Since that time, the timer is activated, after a specified time periodically every 500ms, buzzer is activated until you press the first button.

Etching takes about 10-15 minutes. When aeration is on, top should be covered for example with a rubber band and two holes releasing air, shown in the pictures. It is an effective method to prevent splashing.

Link to original thread (useful attachment) – Wytrawiarka z termostatem i minutnikiem

Last edited: