Vermes

Advanced Member level 4

For this etching tank you need an aquarium with dimensions of 31x21x3cm. Two heaters with a total capacity 250W, aeration stone 30cm long and a digital temperature sensor DS18B20 are put in the aquarium. 1,5l of the solution heats up to a temperature of 40 degrees Celsius in about 15 minutes. The aeration stone in comparison to the normal tube with holes needs more pressure. That is why a large aquarium aerator with a power of 12W should be used.

The dimensions of the aerator can be reduced a little:

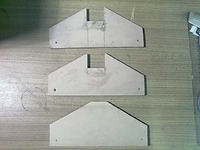

Aquarium base is made of plywood and other wood pieced:

There are two boards in the etching tank. One of them is a power control system with two triacs, detection of zero and power supply +5V for the second board, on which there is Atmega8, LCD display and a buzzer with a generator. Thanks to the detection system of the transition of the voltage through the zero, you can adjust the power of heater and aerator in two different ways: by the phase adjustment, which consists of changing the delay of the moment of enabling the triac after passing the voltage through the zero or group regulation which can be compared to the power control by PWM method. In theory you can simply turn off the heater when the temperature exceeds 41 degrees Celsius and turn on when it drops below this temperature. The aerator is also turned on or off without power control.

After run the etching tank, you can set the time and click start, then the aerator is enabled. While counting the time, you can still add and subtract minutes, enable or disable aeration. After counting the set time, the sound alarm switches on and the aerator switches off. Then you can turn off the sound alarm by any button and turn on the aerator once again. The temperature of 40-41 degrees Celsius is still kept in the aquarium without the possibility to regulate it or turn off the heaters using the menu.

The tube coming out of the machine's back is used to drain the solution. It is finished with a valve.

Link to original thread (useful attachment) – Wytrawiarka PCB by ALN

Last edited: