Vermes

Advanced Member level 4

It is a design of etching station for PCB.

Main assumptions of the project:

- dimensions of the tank: 250x350x20

- driver with microcontroller AVR and alphanumerical LCD display

- home made housing

- air for mixing the solution taken from existing pneumatic installation

- sound signal indicating the end of etching

- temperature sensor DS18B20

Housing:

Sides, top and bottom of the housing were made of 1,5mm thick metal sheet. Panels were made of 4mm thick transparent plexiglass and painted red on one side and painted grey on the other side. In this way, engraved inscriptions are red. There is a hole for the tank in the housing.

Aquarium should be made of glass, because when the solution is heated up, silicone can unglue from the plexiglass.

Motion of the solution is caused by bubbles of air – air is taken from existing pneumatic installation.

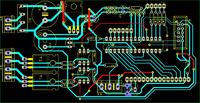

The PCB was designed in Design Spark. Electrovalve and heaters are controlled by triacs. Temperatures sensors were put into a piece of hose and flooded with silicone in order to protect against the solution.

Front panel:

Inside:

PCB:

Video:

List of elements used:

- glass for aquarium

- heaters 2x 80W

- aerating hose

- electrovalve

- LCD 16x2

- transformer

- temperature sensor

- control elements

- metal sheet elements of the housing

- plexiglass for panels

- paints in spray

Link to original thread - Trawiarka do PCB ze sterownikiem na AVR.